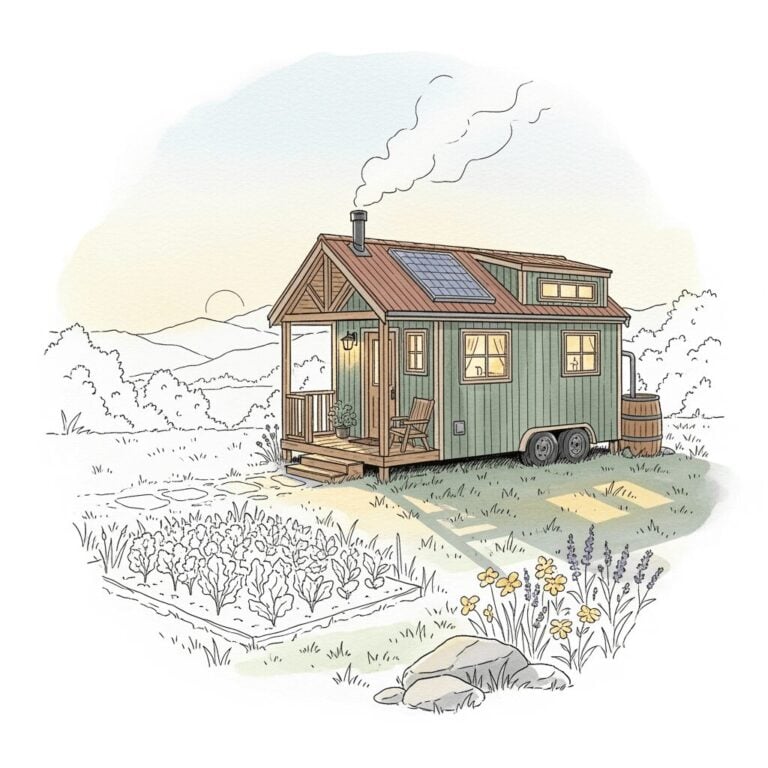

5 Best Solutions for Roof Leaks in Tiny Homes That Save Big

Discover 5 proven solutions to fix roof leaks in tiny homes, from high-quality sealants to flashing repairs. Keep your compact space dry and secure year-round with expert tips.

The big picture: Roof leaks in tiny homes can quickly turn your dream of minimalist living into a costly nightmare that threatens both your investment and daily comfort.

Why it matters: You’re dealing with limited space and resources which means every drop of water that gets through your roof system creates outsized problems – from damaged electronics to structural issues that could compromise your entire home’s integrity.

What’s ahead: We’ve identified five proven solutions that tiny home owners swear by to keep their compact spaces dry and secure year-round.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Identify the Source of Your Tiny Home Roof Leak

Finding your roof leak’s exact location saves you time and money on repairs. Water rarely enters where it shows up inside your tiny home.

Check Common Leak Points Around Vents and Penetrations

Vent boots and pipe penetrations fail more than any other roof component in tiny homes. The rubber seals around your bathroom fan, range hood, and plumbing vents crack from constant temperature changes and UV exposure.

Improve your kitchen's air quality with this 30-inch Broan-NuTone range hood. It features a 2-speed fan, replaceable charcoal filter for effective smoke and odor removal, and cooktop lighting.

Start by checking these seals during daylight hours from inside your loft. Look for light coming through or water stains around the penetration points.

Inspect Flashing Around Skylights and Windows

Organize your family with Skylight Calendar, a 15" touchscreen wall planner. Syncs with popular calendars and features chore charts and meal planning to simplify your daily routines.

Flashing around skylights and windows creates the most persistent leaks in tiny homes. The sealant between your flashing and roofing material breaks down after 3-5 years of weather exposure.

Run your finger along all flashing edges to feel for gaps or soft spots. Pay special attention to the uphill side where water pools and finds its way under loose flashing.

Examine Seam Connections in Metal Roofing

Metal roofing seams open up as your tiny home flexes during transport and settling. These gaps start small but expand with each heating and cooling cycle your roof experiences.

Check every seam connection with a flashlight on sunny days. Water marks on the underside of your roof decking show exactly where seams have failed and need immediate attention.

This compact LED flashlight provides bright illumination up to 492ft. Its adjustable focus lets you switch between spot and flood beams, while the water-resistant design ensures durability.

Apply High-Quality Roof Sealant for Immediate Protection

Once you’ve located your leak source, applying a high-quality roof sealant provides the fastest path to stopping water infiltration. Quality sealants create a waterproof barrier that can last several years when properly applied.

Choose Weather-Resistant Silicone or Polyurethane Sealants

Protect your interior wood projects with Minwax Fast-Drying Polyurethane. This durable, oil-based finish provides long-lasting protection against scratches and spills, and its fast-drying formula allows for quicker project completion.

Silicone sealants excel in extreme temperature conditions and maintain flexibility through freeze-thaw cycles that destroy cheaper alternatives. Dicor Self-Leveling Lap Sealant remains my go-to choice after testing dozens of products on tiny home roofs.

Polyurethane sealants offer superior adhesion to metal surfaces and painted finishes. Sikaflex-221 provides excellent durability for flashing repairs and seam sealing. Both options resist UV degradation far longer than acrylic or latex alternatives that crack within months.

Clean and Prepare the Surface Before Application

Surface preparation determines sealant longevity more than product quality. Remove all loose debris, old sealant remnants, and oxidation using a wire brush or scraper. Clean the area with denatured alcohol to eliminate oils and residue.

Dry surfaces completely before application – even slight moisture prevents proper adhesion. I’ve seen perfectly applied sealants fail within weeks because homeowners skipped this critical step. Wait 24 hours after rain or pressure washing before sealing.

Apply Multiple Thin Coats for Maximum Effectiveness

Thick single applications create weak spots that fail under thermal expansion. Apply your first coat in a thin, even layer using a caulk gun or putty knife. Allow complete curing between coats – typically 24 hours in moderate temperatures.

Second and third coats build thickness gradually while maintaining flexibility. Feather the edges beyond the damaged area to create seamless transitions. This layered approach prevents the cracking and peeling that plague rushed repair jobs.

Install Self-Adhesive Roof Patches for Quick Repairs

Self-adhesive patches offer the fastest permanent solution for small punctures and cracks in tiny home roofs. They’re particularly effective for emergency repairs during storms when you need immediate protection.

Select Patches Compatible with Your Roofing Material

EPDM patches work best on rubber roofing systems and create bonds that often outlast the surrounding membrane. TPO patches require specific adhesives that chemically weld to thermoplastic surfaces.

Metal roofing demands aluminum or galvanized patches with butyl rubber backing. Fiberglass patches excel on RV-style roofs but require primer on smooth surfaces for proper adhesion.

| Roofing Material | Best Patch Type | Special Requirements |

|---|---|---|

| EPDM Rubber | EPDM patches | Clean with alcohol primer |

| TPO | TPO patches | Heat activation recommended |

| Metal | Aluminum patches | Butyl rubber backing essential |

| Fiberglass | Fiberglass patches | Primer required on smooth surfaces |

Ensure Proper Surface Preparation and Adhesion

Surface preparation determines patch longevity more than patch quality. Remove all dirt, chalky residue, and loose material using a wire brush and degreasing agent.

Apply patches during dry conditions between 50-85°F for optimal adhesion. Press firmly from center outward to eliminate air bubbles, which create failure points during thermal expansion.

Wait 24 hours before exposing patches to moisture. This curing period allows adhesives to reach full strength and prevents edge lifting during your first rainstorm.

Monitor Patch Performance During Weather Changes

Temperature swings reveal patch weaknesses within the first month. Check edges for lifting after extreme heat days and inspect for brittleness following freezing nights.

Successful patches remain flexible and maintain tight edge seals regardless of weather conditions. Failed patches show curling edges, color changes, or small separations at corners.

Replace patches showing any edge separation immediately. Small compromises quickly become major leaks during heavy rain or snow loads on your tiny home roof.

Reinforce Vulnerable Areas with Additional Flashing

Strengthening your tiny home’s weakest leak points requires strategic flashing installation beyond what came from the factory. Extra flashing protection transforms potential disaster zones into weatherproof barriers that’ll outlast your original roof.

Add Extra Flashing Around Roof Penetrations

Install metal step flashing around vent pipes and electrical penetrations where factory boot seals commonly fail. Cut L-shaped aluminum pieces that extend 4 inches beyond each penetration. Layer these under your existing roofing material and over the penetration base. This double-barrier system prevents water from finding alternate entry routes when primary seals deteriorate. Professional roofers use this technique on high-end homes because it works.

Use Step Flashing for Chimney and Wall Connections

Step flashing creates an impenetrable water-shedding system where your tiny home’s roof meets vertical walls or chimneys. Cut individual 8-inch square pieces of aluminum flashing. Install each piece under a shingle course and bend it up the wall surface. Overlap consecutive pieces by 2 inches minimum. This staggered installation prevents water from backing up under the flashing during heavy rain or snow melt.

Seal Flashing Edges with Compatible Roofing Cement

Quickly repair roof leaks with Gardner-Gibson Wet Patch Roof Cement. This 10-ounce cartridge creates a strong, waterproof seal on wet or dry surfaces, remaining flexible for lasting protection.

Apply roofing cement along all flashing edges to eliminate micro-gaps that allow water infiltration. Use asphalt-based cement for traditional shingles or polyurethane sealant for metal roofing systems. Work the sealant into corners and transitions where flashing meets roofing material. Check manufacturer compatibility charts before mixing different sealant types. This final sealing step transforms good flashing into bulletproof protection that handles thermal expansion cycles.

Replace Damaged Roofing Sections When Necessary

Sometimes patches and sealants can only take you so far. When roof damage extends beyond what temporary fixes can handle, it’s time to replace entire sections to maintain your tiny home’s integrity.

Assess When Patching Is No Longer Sufficient

Multiple patches in a small area signal it’s time for section replacement. You’ll know patching isn’t working when leaks return within months of repairs or when patches start overlapping.

Look for soft spots that compress under foot pressure – this indicates underlying structural damage. Widespread cracking across a roof panel means the material has reached its lifespan limit and needs complete replacement.

Match New Materials to Existing Roof Components

Check your roof’s manufacturer specifications before ordering replacement materials. TPO, EPDM, and metal roofing each require specific matching products to ensure proper sealing at connection points.

Color matching matters more than you’d think – mismatched sections create hot spots from uneven heat absorption. Take a sample to your supplier or use manufacturer part numbers to guarantee compatibility with existing fasteners and underlayment.

Consider Professional Installation for Complex Repairs

Large section replacements require precise measurements and specialized tools you probably don’t own. Professional installers carry insurance that protects you from costly mistakes during structural work.

Complex repairs involving multiple roof layers or structural modifications need permits in most areas. Contractors handle permitting processes and ensure work meets local building codes, which protects your tiny home’s resale value and insurance coverage.

Conclusion

Your tiny home’s roof protection depends on taking swift action when leaks appear. These five solutions provide you with a comprehensive toolkit that ranges from quick emergency fixes to permanent structural repairs.

Remember that successful roof maintenance isn’t just about fixing current problems—it’s about preventing future issues through regular inspections and proactive care. The money you invest in quality materials and proper repairs today will save you from costly water damage down the road.

Don’t let a small leak turn into a major disaster that threatens your tiny home lifestyle. With these proven solutions in your maintenance arsenal you’ll keep your compact living space dry comfortable and structurally sound for years to come.

Frequently Asked Questions

What are the most common sources of roof leaks in tiny homes?

The most common leak sources include vent boots and pipe penetrations that fail due to temperature changes and UV exposure, flashing around skylights and windows that develop gaps, and seam connections in metal roofing that open over time. Water often enters at different locations than where it appears inside, so thorough inspection of these vulnerable areas is essential.

What type of roof sealant works best for tiny home repairs?

Weather-resistant silicone or polyurethane sealants are recommended. Silicone excels in extreme temperatures and maintains flexibility, while polyurethane offers superior adhesion to metal surfaces. Apply multiple thin coats rather than one thick application, allowing complete curing between coats for maximum durability and effectiveness.

How do I know when to use a roof patch versus a sealant?

Use self-adhesive roof patches for small punctures and cracks, especially during emergencies. Choose EPDM patches for rubber roofs and aluminum patches for metal roofs. Sealants work best for gaps and areas where flexibility is needed. Patches provide permanent solutions for specific damage points.

When should I consider replacing entire roofing sections?

Replace sections when multiple patches appear in small areas, leaks recur shortly after repairs, or you notice structural damage like soft spots that compress under pressure. Widespread cracking also indicates the need for complete replacement rather than continued patching efforts.

Should I hire a professional for complex tiny home roof repairs?

Yes, consider professional installation for complex repairs requiring precise measurements and specialized tools. Contractors handle necessary permits, ensure building code compliance, and protect your tiny home’s resale value and insurance coverage. This is especially important for structural repairs and complete section replacements.