6 Best Roof Insulation Options for Metal Homes That Slash Energy Bills

Effective roof insulation is crucial for metal homes to lower energy bills. We compare the 6 best options, from spray foam to radiant barriers.

I’ve stood inside a metal-sided shop on a summer day and felt the walls radiating heat like a wood stove, and I’ve heard winter condensation dripping from the rafters onto the floor below. Metal buildings are strong, durable, and cost-effective, but they are also thermal super-conductors. Choosing the right insulation isn’t just about comfort; it’s about preventing moisture damage and keeping your energy bills from going through the roof.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Why Metal Roofs Need Specialized Insulation

A metal roof is essentially a giant thermal bridge. In the summer, it absorbs solar radiation and conducts that heat directly into your living space, forcing your AC to work overtime. In the winter, it rapidly loses interior heat to the cold outside air, making your heating system fight a losing battle.

But the bigger enemy is condensation. When the warm, moist air inside your home hits the cold surface of the metal roof, the moisture condenses into water droplets—a phenomenon called "sweating." This moisture can drip onto everything below, saturate traditional insulation, promote mold growth, and even cause rust or rot in your building’s structure.

Proper insulation for a metal roof does three jobs at once. It provides a thermal break to stop heat transfer, it creates an air and vapor barrier to prevent condensation, and it dampens the sound of rain and hail, which can be deafening on an uninsulated metal surface. Skimping here is a recipe for high energy bills and costly moisture problems down the road.

Closed-Cell Spray Foam: Unbeatable R-Value

When you want the absolute best performance and are willing to pay for it, closed-cell spray foam (CCSF) is the answer. This is a two-part polyurethane foam that is professionally sprayed directly onto the underside of your metal roof panels. It expands instantly, filling every crack and crevice to create a seamless, monolithic layer of insulation.

The magic of CCSF is that it’s an all-in-one solution. With an R-value of around R-7 per inch, it offers the highest insulating power on the market. More importantly, its closed-cell structure makes it completely impermeable to both air and water vapor, so it functions as its own perfect air and vapor barrier. This completely eliminates the risk of condensation forming on the metal.

The trade-offs are significant, however. CCSF is the most expensive option and requires professional installation with specialized equipment and safety gear. It’s also permanent; once it’s on, it’s not coming off, which can complicate future repairs or wiring changes. Think of it as the ultimate "do it once, do it right" solution for a lifetime of performance.

Polyiso Rigid Foam Board: High-R Performance

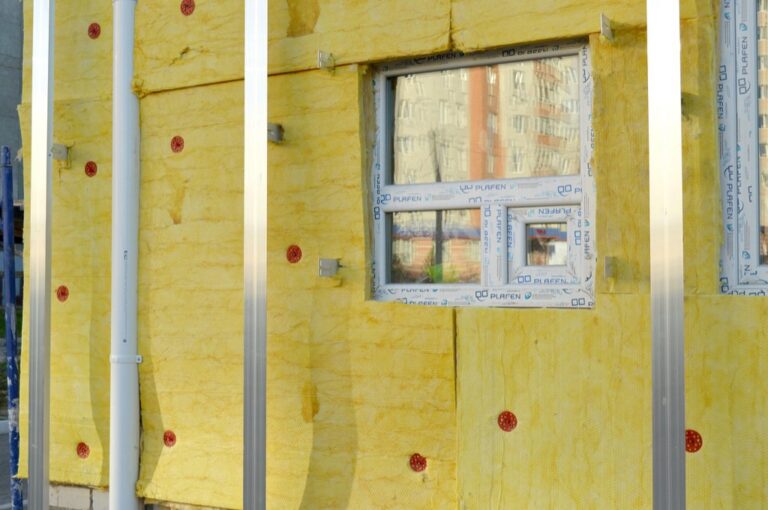

For the dedicated DIYer, polyisocyanurate (Polyiso) rigid foam boards are the next best thing to spray foam. These stiff panels offer a very high R-value, typically around R-6.5 per inch, making them far more effective than traditional pink or white foam boards. They usually come with a foil facing on one or both sides, which adds a radiant barrier effect to help reflect summer heat.

The key to a successful Polyiso installation is meticulous attention to detail. You’ll cut the boards to fit snugly between your roof rafters or purlins, a process often called "cut and cobble." But the most critical step is air sealing. Every single seam between boards and every edge where the foam meets a framing member must be sealed with a high-quality construction tape (like 3M 8067 or Siga Wigluv) or canned spray foam.

If you skip the taping, you’re just creating a puzzle of insulated pieces with air gaps in between. Warm, moist air will find those gaps, hit the cold metal roof, and condense behind your expensive foam boards where you can’t see it. A properly taped Polyiso installation creates a continuous air and vapor barrier, giving you near-spray-foam performance at a fraction of the cost.

Reflectix Radiant Barrier: Blocking Solar Gain

People often misunderstand radiant barriers like Reflectix, thinking of them as traditional insulation. They aren’t. A radiant barrier is essentially a reflective sheet (like bubble wrap sandwiched between foil) that works by blocking radiant heat transfer—the same way a sunshade keeps your car cool. It has a very low R-value and does almost nothing to stop conductive heat loss.

In the right application, a radiant barrier is a powerful tool. Its primary job is to reduce solar gain in hot, sunny climates. To work properly, it must face an air gap of at least 3/4 of an inch. Stapling it directly to the underside of the metal roof renders it useless, as it will just conduct heat through. The best use is installing it below the roof deck with that crucial air gap, where it can reflect up to 97% of radiant heat back out.

Think of a radiant barrier as a specialist, not a general solution. It’s an excellent supplement to other insulation in a hot climate but is not a standalone product for a four-season home. It provides zero sound dampening and won’t keep you warm in the winter, so it must be paired with an insulation that provides a real R-value.

Owens Corning Fiberglass Batts: A Classic Choice

This 2-pack of R-13 Kraft-faced fiberglass insulation rolls provides excellent thermal and sound control for 2x4 walls. Enjoy a comfortable environment with formaldehyde-free, soft-touch insulation.

Fiberglass batts are the cheapest and most common form of insulation, but they are a risky choice for a metal roof. The material itself works by trapping air in its glass fibers to slow heat transfer. It’s inexpensive and easy for any DIYer to roll out and stuff into a cavity.

The problem is moisture. Fiberglass has absolutely no resistance to water; in fact, it acts like a sponge. When condensation inevitably forms on the cold metal, it will drip down and saturate the batts. Wet fiberglass loses all of its insulating R-value and becomes a perfect breeding ground for mold and mildew.

If you absolutely must use fiberglass due to budget constraints, you have to be flawless in your execution. You need a separate, perfectly installed 6-mil poly vapor barrier on the warm side of the insulation, with every seam taped and every staple hole sealed. You also need excellent ventilation in the roof assembly to help dry out any moisture that gets through. It’s a cheap upfront cost that carries a huge risk of failure down the line.

Protect surfaces from moisture and debris with this durable, construction-grade 6 mil polyethylene sheeting. The clear, 10' x 100' roll is easy to cut and ideal for commercial projects, vapor barriers, and dust control.

Rockwool Comfortbatt: Fire & Sound Resistant

Improve building energy efficiency with Rockwool ComfortBoard 80. This durable, high-performance insulation provides superior thermal resistance for exterior walls and roofs.

Rockwool, also known as mineral wool, is a significant step up from fiberglass and an excellent choice for metal homes. Made by spinning molten rock and steel slag into a dense, fibrous material, it offers performance benefits that are perfectly suited to the challenges of a metal structure.

Its two biggest advantages are its resistance to water and fire. Rockwool is hydrophobic, meaning it repels water rather than absorbing it. If condensation does occur, the water will drain through the batt without compromising its structure or R-value. It’s also non-combustible and can withstand temperatures over 2,000°F, adding a critical layer of fire safety to your home.

Beyond that, Rockwool is an incredible sound absorbent. Its density makes it far more effective at deadening sound than fiberglass, turning the roar of a rainstorm on your metal roof into a gentle patter. While it’s more expensive and a bit messier to cut than fiberglass, its superior moisture, fire, and sound performance make it a much smarter and safer investment.

SIPs (Structural Panels): All-in-One Solution

Structural Insulated Panels, or SIPs, aren’t an insulation you add—they are the structure itself. A SIP is a sandwich made of a thick core of rigid foam (like EPS or Polyiso) laminated between two sheets of structural board, typically OSB (Oriented Strand Board). These panels are used to frame the walls and roof of a building.

The beauty of building with SIPs is that you get your structure, sheathing, and a continuous layer of high-R-value insulation in one step. Because the panels are large and the foam core is solid, they create an incredibly airtight and well-insulated building envelope with very few thermal bridges. This approach virtually eliminates any chance of condensation and dramatically simplifies construction.

Of course, this is a solution you must choose at the design phase of a new build, not a retrofit option for an existing roof. The upfront cost for the panels can be higher than traditional stick framing and separate insulation. However, the savings in labor time and long-term energy performance often make SIPs a cost-effective choice for a new metal-roofed home or cabin.

Comparing Costs, R-Value, and Installation

Choosing the right insulation comes down to balancing performance, cost, and your ability to install it correctly. A high-R-value product installed poorly will perform worse than a lower-R-value product installed perfectly. For a metal roof, managing moisture is just as important as R-value.

Here’s a quick breakdown to help you decide:

- Highest Performance & Cost: Closed-Cell Spray Foam. Pro-install only. The ultimate set-it-and-forget-it solution that solves heat transfer and condensation in one application.

- Best DIY High-Performance: Polyiso Rigid Foam. Requires meticulous cutting and taping of all seams to create an air/vapor barrier. High R-value for the money if you have the patience.

- Best for Sound & Safety: Rockwool. A fantastic DIY-friendly option that is forgiving with moisture, non-combustible, and provides superior sound dampening. A great all-arounder.

- Budget (with High Risk): Fiberglass Batts. Only attempt this if you are an expert at installing a flawless vapor barrier. The low upfront cost can lead to very expensive mold and rot problems.

- Best for New Builds: SIPs. An integrated system that provides structure and insulation in one. Excellent performance but must be part of the initial building design.

- Specialist Tool (Hot Climates): Radiant Barrier. Use it as a supplement to another insulation, not as a standalone solution. Requires an air gap to function.

Ultimately, your climate, budget, and building stage will dictate the best path. Don’t just chase the highest R-value on the label. Focus on the system that will provide a continuous thermal break and a bulletproof barrier against condensation. Get that combination right, and your metal home will be comfortable, efficient, and durable for decades.

Insulating a metal roof is less about the material itself and more about the system you create. Your primary goal is to stop air movement and prevent warm, moist interior air from ever touching the cold metal sheathing. Whether you achieve that with spray foam’s monolithic seal or the careful taping of rigid foam boards, a truly airtight and vapor-tight installation is the only way to win the war against condensation and high energy bills.