7 Minimalist Tool Organization Strategies for Small Spaces That Maximize Every Inch

Discover 7 space-saving tool organization strategies for small workshops. From vertical storage to multi-functional containers, maximize your workspace efficiently.

Why it matters: Your cramped workshop or tiny garage doesn’t have to mean sacrificing functionality for space. Smart tool organization transforms chaotic small spaces into efficient work zones where every screwdriver and wrench has its perfect place.

The challenge: Most storage solutions ignore the unique constraints of compact areas and leave you wrestling with cluttered drawers and inaccessible equipment. Traditional organization methods simply don’t work when you’re dealing with limited square footage and awkward layouts.

What’s ahead: These seven minimalist strategies will help you maximize every inch while keeping your essential tools within arm’s reach.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Embrace Vertical Wall Storage Solutions

Your walls are prime real estate in small spaces. They’re the most underutilized storage area in cramped workshops and tiny garages.

Install Pegboard Systems for Maximum Flexibility

Organize your space with this 300-piece pegboard hook set. Durable metal hooks fit 1/8" and 1/4" pegboards, offering versatile storage for tools, crafts, and more.

Pegboards transform any wall into a customizable tool organizer. You’ll arrange hooks, shelves, and bins exactly where you need them.

Standard 1/4-inch pegboard costs under $30 per 4×8 sheet. Mount it 6 inches from the wall to accommodate deeper tools like drills and sanders. You can reconfigure your setup as your tool collection changes.

Use Magnetic Tool Strips for Quick Access

Organize your tools with this durable, wall-mounted magnetic holder. The heavy-duty magnetic strip keeps pliers, wrenches, and screwdrivers readily accessible, while included mounting screws ensure easy installation.

Magnetic strips keep metal tools visible and within arm’s reach. You’ll grab screwdrivers, wrenches, and pliers without digging through drawers.

Install 18-inch magnetic bars above your workbench for immediate access. They hold up to 30 pounds and work perfectly for frequently used hand tools. Your most essential tools stay organized at eye level.

Mount Shadow Boards for Visual Organization

Keep your workspace organized with this 5S shadow board broom station. The blue board clearly displays missing items and ensures tools are always returned to their designated place.

Shadow boards show exactly where each tool belongs through painted outlines. You’ll spot missing tools instantly and maintain perfect organization.

Create templates using your actual tools on 1/4-inch plywood. Paint the board white and trace tool outlines in black. This system works especially well for socket sets, hex keys, and specialty tools that easily get misplaced.

Maximize Drawer Space With Smart Dividers

After years of living with limited storage, I’ve learned that drawers are gold mines of wasted space. Most people just toss tools into drawers and hope for the best, but smart dividers can triple your storage capacity while keeping everything perfectly organized.

Create Custom Foam Inserts for Tool Protection

Get custom-cut foam for cushions and DIY projects in your desired size and density. Choose from high or medium density polyurethane foam for reliable support and lasting shape.

Foam inserts are the ultimate drawer hack for protecting expensive tools. Cut dense foam to fit your drawer dimensions, then trace and cut out tool shapes with a craft knife. This creates a perfect nest for each tool that prevents scratching and movement during travel.

I use 2-inch thick foam for my precision instruments like calipers and micrometers. The visual outline also makes it obvious when tools are missing, which saves time during projects.

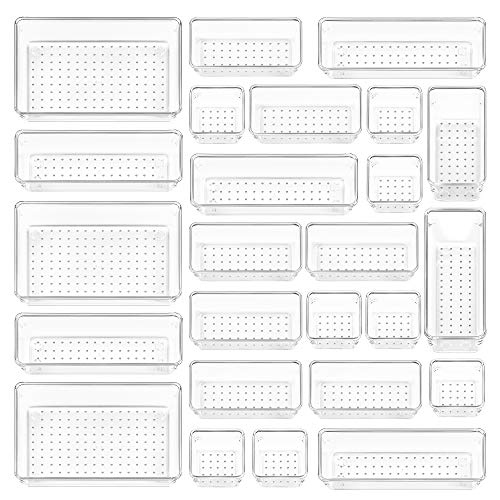

Use Adjustable Drawer Organizers for Versatility

Adjustable dividers adapt as your tool collection changes. Spring-loaded dividers from brands like Rev-A-Shelf or simple plastic organizers let you reconfigure compartments without permanent modifications. This flexibility is crucial in small spaces where every drawer serves multiple purposes.

I’ve found that modular systems work best for general hand tools like screwdrivers and pliers. You can create narrow slots for thin tools and wider sections for bulkier items as needed.

Implement Shallow Drawer Systems for Small Tools

Shallow drawers prevent small tools from getting buried under larger ones. Install drawer slides rated for 100+ pounds and create 2-3 inch deep compartments. This works perfectly for drill bits, screws, and electrical components that typically disappear in deep drawers.

Consider installing pull-out trays in existing deep drawers. This doubles your accessible storage and keeps frequently used items at eye level where you can grab them instantly.

Utilize Multi-Functional Storage Containers

Organize your pantry with this 24-piece airtight container set. The stackable, BPA-free canisters keep food fresh and include reusable labels for easy identification.

Smart storage containers do double duty in small spaces, eliminating the need for separate organizational systems. The key is choosing containers that maximize both storage capacity and accessibility.

Choose Stackable Tool Boxes for Efficiency

Stackable tool boxes create vertical storage towers that grow with your collection. I’ve found that modular systems with interlocking bases prevent dangerous toppling while maintaining easy access to lower levels.

Look for boxes with clear lids and removable dividers. This combination lets you see contents at a glance and customize compartments as your tool needs change over time.

Invest in Rolling Tool Carts With Multiple Tiers

Rolling carts transform dead floor space into mobile workstations that follow you around your workspace. Multi-tier designs effectively triple your surface area while keeping everything within arm’s reach.

Choose carts with locking wheels and varied shelf heights. The locks prevent unwanted movement during detailed work, while different shelf dimensions accommodate everything from small hardware to power tools.

Select Clear Storage Bins for Easy Identification

Clear bins eliminate the guesswork that wastes precious time in cramped spaces. You’ll spend less time searching and more time working when every container reveals its contents instantly.

Opt for stackable rectangular bins over round ones to maximize shelf efficiency. Square corners and flat sides create 30% more usable storage volume in the same footprint.

Implement the One-In-One-Out Rule

Maintaining an organized tool collection in small spaces requires strict discipline about what enters and exits your workspace. The one-in-one-out rule prevents tool accumulation from overwhelming your carefully planned storage systems.

Assess Tool Necessity Before Adding New Items

Evaluate every potential tool purchase against your actual work requirements. Ask yourself if this new tool performs a function that existing tools can’t handle or if it significantly improves efficiency on regular tasks.

Create a simple decision matrix rating new tools on frequency of use, space efficiency, and overlap with current equipment. Tools scoring low across all categories rarely justify their footprint in cramped workshops.

Donate or Sell Duplicate Tools Regularly

Duplicate tools multiply faster than you’d expect, especially when inheriting equipment or buying combo sets. Review your collection monthly to identify redundant items that consume valuable storage space.

Focus on keeping the highest-quality version of each tool type while removing worn-out or inferior duplicates. Local maker spaces, trade schools, and community workshops often welcome donated tools that still have useful life remaining.

Focus on Quality Over Quantity for Tool Selection

Investing in fewer, higher-quality tools maximizes both performance and space efficiency. Professional-grade tools typically offer better durability, more compact designs, and superior functionality compared to budget alternatives.

One high-quality multi-tool often replaces three separate inferior tools while occupying less storage space. This approach reduces clutter while ensuring your essential tools perform reliably when you need them most.

Create Designated Zones for Different Tool Categories

Group similar tools together to streamline your workflow and eliminate the frustration of searching through mixed collections. Strategic zoning transforms chaotic tool storage into an efficient system where everything has its logical place.

Establish a Power Tool Station

Dedicate one area exclusively to power tools and their accessories. Mount a pegboard near an electrical outlet to keep chargers accessible while providing hooks for drills, drivers, and sanders. Store batteries in a small drawer organizer directly below the tools they power.

Create a charging station using a power strip mounted inside a cabinet door. This keeps cords organized while protecting batteries from dust and temperature fluctuations that can reduce their lifespan.

Design a Hand Tool Area

Position frequently used hand tools at eye level within arm’s reach of your primary workspace. Install a narrow shelf or magnetic strip for screwdrivers, pliers, and wrenches you grab multiple times per project. Keep measuring tools like rulers and squares in a designated vertical slot.

Use a small toolbox or caddy for precision instruments like calipers and gauges. This protects delicate tools while keeping them separate from heavier items that could cause damage through contact.

Set Up a Hardware and Fastener Zone

Convert a small drawer or cabinet section into a dedicated hardware hub using clear compartmented containers. Sort screws, bolts, and washers by size and type rather than mixing them together. Label each compartment with both size and common applications.

Mount a rotating hardware organizer on the wall if drawer space is limited. These carousel-style units maximize vertical storage while keeping small parts visible and accessible during projects.

Optimize Unused Spaces Throughout Your Home

Your home contains dozens of overlooked storage opportunities that can house your entire tool collection without sacrificing living space. These forgotten zones often provide better organization than traditional storage areas.

Transform Cabinet Doors Into Tool Storage

Cabinet doors offer premium real estate that’s usually wasted on empty air. Install narrow shelves or pegboard strips on the inside of kitchen cabinet doors to hold screwdrivers, pliers, and measuring tools.

Over-the-door shoe organizers work brilliantly for small hardware and drill bits. You’ll keep everything visible while maintaining easy access during projects. The key is choosing lightweight tools that won’t strain hinges over time.

Use Under-Stair Areas for Bulky Equipment

Under-stair storage naturally accommodates your largest tools without consuming floor space elsewhere. Build or install pull-out drawers that follow the stair slope to maximize every inch of available height.

This space perfectly houses table saws, shop vacuums, and compressors that you don’t need daily access to. Add LED strip lighting and ventilation to create a proper mini-garage. The triangular shape actually works in your favor for storing oddly-shaped equipment.

Convert Closet Corners Into Mini Workshops

Corner spaces in closets create perfect tool command centers when you install rotating lazy Susan shelves. These carousel systems let you store three times more tools than traditional shelving while keeping everything within arm’s reach.

Mount a small pegboard on the back wall and add a fold-down work surface for quick repairs. You’ll have a complete workshop that disappears behind a closet door. Choose corners in bedrooms or hallways where you won’t disturb others during evening projects.

Maintain Your Minimalist Tool Organization System

Your perfectly organized tool setup won’t stay perfect without consistent maintenance habits. I’ve watched too many well-intentioned systems fall apart within months because people skip the upkeep that makes minimalist organization actually work.

Schedule Weekly Tool Inventory Sessions

Set aside 15 minutes every Sunday to walk through your tool zones. Check that each tool’s in its designated spot and note any items that consistently end up in the wrong place.

This isn’t about perfectionism—it’s about catching problems before they become chaos. Missing tools, loose hardware, and misplaced items reveal patterns that help you refine your system over time.

Clean and Return Tools Immediately After Use

Clean your tools while the project debris is still fresh. Dried concrete, paint, or sawdust becomes exponentially harder to remove later and can damage your equipment.

The “immediate return” rule prevents the dreaded tool pile-up on your workbench. I’ve found that tools left out for “just tonight” often stay there for weeks, gradually destroying your organized zones.

Review and Adjust Organization Methods Quarterly

Evaluate what’s working and what isn’t every three months. Your tool collection evolves, and your storage methods should adapt accordingly.

Look for frequently used tools stored in hard-to-reach spots, containers that consistently overflow, and zones that feel cramped. Small adjustments—moving a toolbox, adding a hook, or swapping container sizes—keep your system functional as your needs change.

Conclusion

Organizing tools in small spaces doesn’t have to be overwhelming when you apply these minimalist strategies. By focusing on vertical storage solutions and multi-functional containers you’ll maximize every square inch while keeping your essential tools accessible.

Remember that successful tool organization is an ongoing process. The key is implementing systems that work for your specific space and workflow then maintaining them through consistent habits.

Start with one strategy that resonates most with your current challenges. Whether it’s installing a pegboard system or creating designated zones you’ll quickly see how these approaches transform your cramped workspace into an efficient organized environment.

Your small space can become just as functional as any large workshop when you embrace smart storage solutions and resist the urge to accumulate unnecessary tools.

Frequently Asked Questions

What are the best vertical storage solutions for small workshops?

Pegboard systems offer the most flexibility, allowing you to customize hook and shelf arrangements as your tool collection changes. Magnetic tool strips provide quick access to metal tools while keeping them visible. Shadow boards help maintain organization by visually indicating where each tool belongs, making it easy to spot missing items.

How can I maximize storage space in small drawers?

Use smart dividers and adjustable drawer organizers to triple your storage capacity. Create custom foam inserts to protect expensive tools and prevent movement. Install shallow drawer systems for small tools and add pull-out trays to deep drawers to make everything easily accessible.

What types of containers work best for tool organization?

Stackable tool boxes create vertical storage towers and save floor space. Rolling tool carts with multiple tiers transform dead space into mobile workstations. Clear storage bins enhance visibility and efficiency, while rectangular shapes maximize shelf space better than round containers.

How do I prevent my tool collection from getting too cluttered?

Implement the one-in-one-out rule before purchasing new tools. Use a decision matrix to evaluate whether new tools are truly necessary and space-efficient. Regularly donate or sell duplicate tools, and focus on investing in fewer, higher-quality tools that can replace multiple inferior ones.

What’s the best way to organize different types of tools?

Create designated zones for different tool categories. Set up a power tool station with accessible chargers and battery storage. Design a hand tool area with frequently used items at eye level. Establish a hardware zone using clear containers and wall-mounted organizers for easy sorting.

How can I use unused spaces in my home for tool storage?

Transform cabinet doors by installing narrow shelves or pegboard strips. Use over-the-door shoe organizers for small hardware. Convert under-stair areas with pull-out drawers and proper lighting. Turn closet corners into mini workshops with rotating lazy Susan shelves and fold-down work surfaces.

How do I maintain my organized tool system over time?

Schedule weekly tool inventory sessions to ensure everything stays in its designated spot. Follow the “immediate return” rule by cleaning and returning tools right after use. Review and adjust your organization methods quarterly to adapt to changes in your tool collection and storage needs.