7 Steps to Manage Tiny Home Building Timelines That Save Money

Master your tiny home build with 7 proven timeline strategies. Avoid costly delays, manage permits & contractors, plus weather contingency planning tips.

Building a tiny home can quickly turn into a massive headache if you don’t nail down your timeline from day one. Most first-time builders underestimate construction schedules by 30-50% and end up facing costly delays that blow their budgets sky-high.

The bottom line: A solid timeline isn’t just nice to haveâit’s your roadmap to avoiding financial disaster and actually moving into your dream tiny home on schedule.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Step 1: Create a Detailed Project Timeline With Realistic Milestones

Your timeline becomes the backbone of your entire tiny home project. Without specific milestones and realistic deadlines, you’ll find yourself months behind schedule and thousands over budget.

Break Down Each Building Phase Into Manageable Tasks

Foundation and framing work differently than interior finishing. You can’t treat them as single massive chunks on your calendar. Foundation prep takes 3-5 days, while trailer assembly requires another 2-3 days with proper equipment.

Break framing into wall construction, roof assembly, and sheathing installation. Each phase has distinct material deliveries and weather dependencies. Interior work splits into electrical rough-in, plumbing installation, insulation, and finish work phases that can’t overlap without creating expensive rework scenarios.

Account for Permit Approval and Inspection Delays

Permit offices don’t operate on construction timelines. Municipal approval processes typically take 2-6 weeks, depending on your location and project complexity. Some jurisdictions require multiple plan revisions before approval.

Schedule inspections early and expect 1-2 week delays between submission and actual inspection dates. Electrical and plumbing inspections often require specific completion stages that can’t be rushed. Failed inspections mean additional weeks of delays while you correct issues and reschedule follow-up visits.

Build in Buffer Time for Unexpected Challenges

Weather delays hit tiny home projects harder than traditional construction. Rain stops exterior work completely, and high winds make roof installation dangerous. Add 20-30% buffer time to your overall timeline for weather-related delays alone.

Material delivery delays become project killers when you’re working with specialized tiny home components. Custom windows, compact appliances, and engineered lumber often have 4-8 week lead times. One delayed shipment pushes back multiple phases of work, creating cascading schedule problems that compress your entire timeline.

Step 2: Secure All Permits and Documentation Before Breaking Ground

Getting your permits sorted early saves you from costly delays and potential legal headaches. Most builders think they can start the permit process while breaking ground, but that’s a recipe for disaster.

Research Local Zoning Laws and Building Codes

You’ll need to dig deep into your local building codes before designing your tiny home. Each municipality has different requirements for minimum square footage, foundation types, and utility connections that can completely change your build plan.

Start by calling your local building department directly rather than relying on online information. Code enforcement officers often know about upcoming changes or special considerations that aren’t published yet, and they’re usually happy to help serious builders.

Submit Applications Early to Avoid Delays

Plan to submit your permit applications at least 8-12 weeks before you want to start building. I’ve seen permit approval take anywhere from 4 weeks to 6 months depending on your location and the complexity of your design.

Most jurisdictions require multiple rounds of revisions, especially for non-traditional builds like tiny homes. Submit your initial application knowing you’ll likely need to make changes, and factor those revision cycles into your timeline from the start.

Keep All Paperwork Organized and Accessible

Create both digital and physical files for all your permit documents, correspondence, and approved plans. You’ll need quick access to these papers during inspections, and building inspectors don’t appreciate waiting while you search through your phone.

Keep copies of your approved plans on-site at all times during construction. Store them in a waterproof container, and make sure anyone working on your build knows where to find them when inspectors show up unexpectedly.

Step 3: Order Materials and Supplies in Strategic Phases

Smart material ordering prevents construction delays and reduces storage challenges on your tiny home site. You’ll avoid the common mistake of ordering everything at once and then scrambling to find storage space while materials weather and deteriorate.

Create a Material Delivery Schedule Aligned With Construction Phases

Order foundation materials first, scheduling delivery 1-2 weeks before your planned foundation pour date. This includes concrete, rebar, and vapor barriers that can handle brief weather exposure.

Frame your delivery schedule around your construction timeline. Lumber arrives just before framing begins, roofing materials ship when you’re ready for the roof phase, and finish materials like flooring and cabinetry arrive during the final 30% of construction.

Establish Relationships With Reliable Suppliers

Build partnerships with 2-3 local suppliers who understand tiny home projects and can accommodate smaller order quantities. Many big-box stores struggle with the specialized materials and timing requirements of compact builds.

Ask suppliers about their delivery windows and minimum order requirements upfront. Some materials like windows and specialty lumber require 4-8 week lead times, while standard framing lumber typically ships within days.

Plan for Weather-Related Delivery Delays

Weather delays affect 40% of material deliveries during winter months and rainy seasons, according to construction industry data. Schedule critical deliveries during your region’s most predictable weather windows.

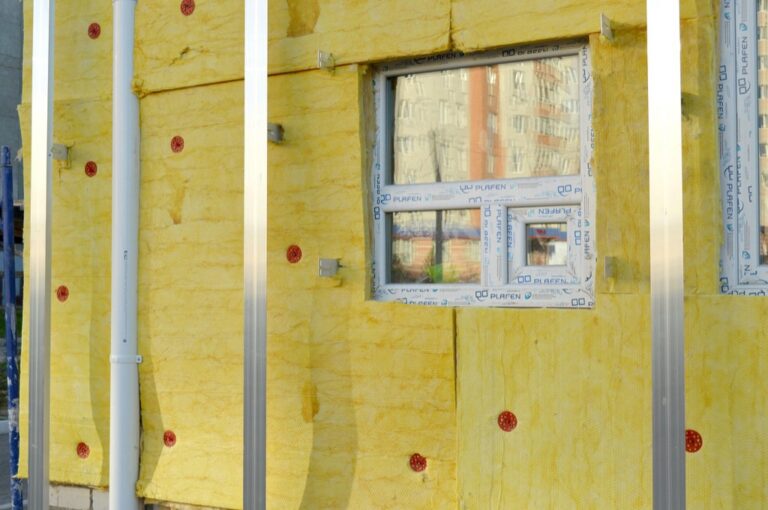

Create backup storage plans for weather-sensitive materials like drywall and insulation. Rent a small storage unit or arrange covered staging areas before deliveries arrive, especially if your build site lacks adequate protection.

Step 4: Coordinate Contractor Schedules and Availability

Contractor coordination separates successful tiny home builds from disaster stories. You’ll juggle multiple trades while working with professionals who might not fully understand tiny home construction timelines.

Book Specialized Contractors Well in Advance

Electrical and plumbing contractors book up 6-8 weeks ahead in most markets, especially during peak construction seasons. Tiny home projects require specialized knowledge that not all contractors possess.

Start reaching out to contractors during your permit phase. Ask specifically about their tiny home experience and availability for multi-day windows. Many contractors prefer clustered work schedules for smaller projects like yours, so flexibility in your timeline becomes crucial for securing quality professionals.

Create a Communication System for Schedule Updates

Group text messaging or project management apps work better than email chains for real-time schedule coordination. Weather delays and material shortages happen frequently, requiring immediate communication adjustments.

Send weekly schedule updates to all contractors, even when nothing changes. Include photos of progress and any site conditions that might affect their work. This proactive approach prevents contractors from showing up to incomplete phases or unsuitable working conditions that waste everyone’s time.

Have Backup Plans for Contractor Conflicts

Keep contact information for at least two contractors per trade throughout your project timeline. Primary contractors get sick, face family emergencies, or encounter scheduling conflicts that can derail your entire build sequence.

Maintain relationships with backup contractors by sending occasional project updates and timeline forecasts. Consider paying small retainer fees to priority backup contractors during critical phases like electrical rough-in or final inspections, where delays create expensive ripple effects throughout your remaining construction schedule.

Step 5: Monitor Progress Weekly and Adjust Timelines as Needed

Weekly progress monitoring transforms tiny home builds from chaotic scrambles into controlled construction projects. You’ll catch problems early and make informed adjustments before small delays snowball into major setbacks.

Conduct Regular Site Inspections and Progress Reviews

Schedule your site visits every Tuesday and Friday to maintain consistent oversight of construction progress. Walk through each work area with a checklist, photographing completed tasks and noting any quality concerns or deviations from your approved plans.

Compare actual progress against your timeline milestones weekly. If framing should be 75% complete but you’re only at 60%, you’ll know immediately that adjustments are needed rather than discovering the delay when the electrician arrives next week.

Document Delays and Their Root Causes

Create a simple delay log using your phone or a notebook to track every setback with its specific cause and duration. Record weather delays, material shortages, contractor no-shows, and permit hold-ups with timestamps and photos when relevant.

This documentation becomes invaluable for future timeline adjustments and helps you identify patterns. If your plumber has been late three times due to supply issues, you’ll know to order plumbing materials earlier for the next phase.

Communicate Changes to All Stakeholders Immediately

Send timeline updates to your entire team within 24 hours of identifying any delays or schedule changes. Use group texts or project management apps to keep contractors, suppliers, and family members informed about revised completion dates and upcoming work phases.

Update your material delivery schedule immediately when construction phases shift. A two-day framing delay means your electrical rough-in materials should arrive Thursday instead of Tuesday, preventing unnecessary site storage and potential theft or weather damage.

Step 6: Prepare for Common Setbacks and Weather Delays

Weather delays can derail even the most carefully planned tiny home timeline. Smart builders plan for Mother Nature’s curveballs by identifying vulnerable seasons and creating flexible work schedules.

Identify High-Risk Weather Seasons in Your Area

Research your local weather patterns to pinpoint the most challenging months for construction. Most regions experience 2-3 months of severe weather that can halt outdoor work completely.

Spring brings unpredictable storms and muddy conditions that prevent foundation work. Summer heat waves can make roofing dangerous and slow concrete curing. Winter frost stops most exterior tasks and creates material delivery challenges.

Check historical weather data for your area to identify patterns. Mark these high-risk periods on your timeline and avoid scheduling critical outdoor phases during these windows.

Plan Indoor Work During Poor Weather Conditions

Rainy days don’t have to mean zero progress if you’ve prepared indoor tasks in advance. Interior work like electrical wiring, insulation installation, and cabinet assembly can continue regardless of outside conditions.

Create a “weather backup” schedule that prioritizes indoor phases during storm seasons. Stock up on interior materials early so you’re not waiting for deliveries during bad weather. Focus on plumbing rough-in, drywall prep, and finish carpentry when outdoor work isn’t possible.

Keep essential tools and materials protected in weatherproof storage so they’re ready when conditions improve.

Create Alternative Task Lists for Unexpected Downtime

Develop three separate task lists for different delay scenarios: weather delays, material shortages, and contractor no-shows. This prevents wasted time when your primary schedule gets disrupted.

Your weather delay list might include sanding, painting prep, and organizing materials. Material shortage tasks could involve site cleanup, tool maintenance, and permit paperwork review. Contractor delay activities might focus on DIY tasks you can handle independently.

Update these alternative lists weekly as your project progresses. Having productive backup plans keeps momentum going even when setbacks occur.

Step 7: Establish Clear Communication Channels With Your Team

Communication breakdowns kill more tiny home projects than material delays or weather setbacks. You’ll need structured systems to keep everyone aligned and your timeline on track.

Set Up Regular Check-In Meetings With Contractors

Schedule weekly progress meetings every Friday afternoon to review the upcoming week’s tasks and address potential conflicts. I’ve found that 30-minute calls work better than lengthy in-person meetings for busy contractors.

Create a standard agenda covering completed work, next week’s priorities, and any roadblocks. Send contractors a brief update form 24 hours before each meeting so they can prepare specific questions and concerns. This approach prevents contractors from making assumptions about site readiness and helps you catch scheduling conflicts before they derail your timeline.

Use Project Management Tools for Real-Time Updates

Digital project management platforms like Buildertrend or Procore streamline communication between all team members. These tools let contractors upload progress photos, mark tasks complete, and flag delays instantly.

Set up automated notifications for milestone completions and schedule changes. Upload your construction drawings and permit documents directly to the platform so contractors can access current plans without calling you. Most contractors already use these systems for larger projects, making adoption easier than you’d expect.

Maintain Open Lines of Communication With Suppliers and Inspectors

Establish direct contact with your material suppliers and request their cell phone numbers for urgent delivery updates. Text them the night before scheduled deliveries to confirm timing and site accessibility.

Build relationships with local inspectors by scheduling informal pre-inspection walkthroughs. Most inspectors appreciate builders who communicate potential issues early rather than discovering problems during official inspections. Keep inspection request forms pre-filled and submit them 48 hours before you need scheduling to avoid delays in your construction sequence.

Conclusion

Managing your tiny home building timeline doesn’t have to be overwhelming when you follow these strategic steps. You’ll save both time and money by planning ahead and staying organized throughout the construction process.

Remember that flexibility is your greatest asset when building a tiny home. Weather delays material shortages and contractor scheduling conflicts are all part of the journey. Your success depends on how well you adapt to these challenges while keeping your project moving forward.

The key to timeline success lies in consistent communication and proactive planning. When you establish clear expectations with your team and build in adequate buffer time you’re setting yourself up for a smoother construction experience.

Your dream tiny home is achievable with the right approach to timeline management. Start implementing these strategies today and you’ll be amazed at how much more control you have over your building schedule.

Frequently Asked Questions

How much buffer time should I add to my tiny home construction timeline?

Add 20-30% buffer time to your original construction timeline. This accounts for unexpected challenges like weather delays, material delivery issues, and permit complications. For example, if your initial timeline is 6 months, plan for 7.5-8 months total to avoid stress and budget overruns.

When should I start the permit application process for my tiny home?

Submit permit applications 8-12 weeks before you want to start construction. Approval times can range from 4 weeks to 6 months, often requiring multiple revisions. Starting early prevents costly delays and ensures you have all necessary documentation before breaking ground.

How far in advance should I book contractors for my tiny home build?

Book specialized contractors during the permit phase, typically 2-3 months before you need them. Electrical and plumbing professionals often have busy schedules, especially during peak construction seasons. Early booking ensures you secure quality professionals and avoid scheduling conflicts.

What’s the best way to coordinate material deliveries for a tiny home project?

Create a material delivery schedule aligned with construction phases, starting with foundation materials and framing supplies. Order materials 2-4 weeks before you need them, considering lead times for specialized components. This prevents storage challenges and ensures materials arrive when needed.

How often should I monitor progress during tiny home construction?

Conduct weekly site inspections and progress reviews. Schedule regular visits to maintain oversight and catch potential issues early. Document any delays and their causes in a delay log to identify patterns and make informed timeline adjustments.

What backup plans should I have for weather-related construction delays?

Research local weather patterns to identify high-risk seasons and create flexible work schedules. Plan indoor tasks like electrical work and interior finishing during poor weather conditions. Develop alternative task lists for various delay scenarios to maintain project momentum.

How can I ensure effective communication with my tiny home construction team?

Set up regular check-in meetings with contractors to review progress and address conflicts. Use project management tools or group messaging apps for real-time updates. Send weekly progress reports with photos to keep all team members informed and aligned.

What permits and documentation do I need before starting tiny home construction?

Research local zoning laws and building codes, as requirements vary by municipality. Obtain building permits, electrical permits, and plumbing permits before construction begins. Keep all approved plans organized and accessible on-site during inspections to avoid delays.