7 Pros and Cons of Hydraulic Leveling Systems That Enable RV Freedom

Discover the pros and cons of hydraulic RV leveling systems. From push-button convenience and superior stability to high costs and maintenance needs – get the full breakdown.

You’ve probably seen those massive RVs that can level themselves with the push of a button – that’s hydraulic leveling technology at work. These systems use pressurized fluid to automatically adjust your vehicle’s stance on uneven terrain making camping and parking infinitely easier. But like any advanced technology hydraulic leveling systems come with both game-changing benefits and potential drawbacks you need to understand before investing.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Understanding Hydraulic Leveling Systems: What They Are and How They Work

Level and stabilize your 5th wheel RV in minutes with the Lippert Ground Control 3.0. This automatic 6-point system features Hall Effect technology for precise leveling and a durable, heavy-gauge steel construction.

Hydraulic leveling systems use pressurized fluid and mechanical actuators to automatically adjust your RV’s position on uneven surfaces. This technology transforms what used to be a 30-minute manual process into a simple button press.

Basic Components and Mechanics

The system consists of four main parts: hydraulic jacks at each corner, a pump that pressurizes fluid, sensors that detect your RV’s level, and a control panel. When you activate the system, sensors measure tilt angles while the pump sends hydraulic fluid to extend or retract individual jacks until your RV achieves perfect level. Most systems operate on 12V power and can lift up to 20,000 pounds per jack.

Lift up to 4 tons with the Torin Big Red Hydraulic Bottle Jack. Its durable steel construction and wide base provide stability, while the adjustable screw top offers versatile lifting from 7-1/2" to 14-5/16".

Common Applications in RVs and Heavy Equipment

You’ll find hydraulic leveling in Class A motorhomes, luxury fifth wheels, and travel trailers over 30 feet. The technology originated in construction equipment like excavators and cranes before manufacturers adapted it for recreational vehicles. Today’s systems can level your RV on slopes up to 6 degrees and typically complete the process in under 2 minutes, making them essential for boondocking and uneven campsites.

Protect and upgrade your RV seats with these durable, easy-to-clean PVC leatherette covers. The GripFit+ design ensures a snug fit, while convenient side pockets offer extra storage.

Pro #1: Superior Stability and Precision Leveling

Hydraulic leveling systems deliver unmatched accuracy that manual leveling simply can’t match. You’ll achieve perfectly level positioning every time, eliminating the guesswork and frustration of traditional methods.

Exact Positioning Capabilities

You’ll get precision down to 0.5 degrees with quality hydraulic systems, compared to 2-3 degrees with manual leveling blocks. The integrated sensors continuously monitor your RV’s position and make micro-adjustments automatically. This level of accuracy ensures your refrigerator operates efficiently, doors close properly, and you sleep comfortably without rolling to one side of the bed.

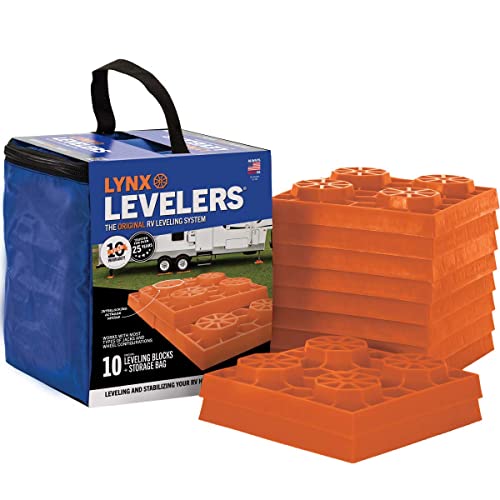

Level your RV easily and securely with the Tri-Lynx Lynx Levelers. This 10-pack supports up to 40,000 pounds and features a modular design for customized leveling on any terrain.

Reduced Manual Effort Required

You’ll transform a 30-minute workout into a 2-minute button press with hydraulic leveling. No more crawling under your RV with heavy blocks or wrestling with manual jacks in tight spaces. The system handles weight distribution automatically, lifting up to 20,000 pounds per jack while you monitor progress from inside your RV through the control panel.

Pro #2: Enhanced Safety Features and Reliability

Hydraulic leveling systems incorporate multiple safety mechanisms that manual leveling simply can’t match. You’ll get automatic stabilization and protection features that reduce both physical risk and equipment damage.

Automatic Stabilization Benefits

You’ll experience significantly improved safety with hydraulic systems’ built-in stabilization features. The system automatically prevents over-extension of jacks beyond safe limits, protecting against tip-over risks that can occur with manual leveling.

Most systems include emergency stop functions and automatic retraction if sensors detect unsafe conditions. You’ll also get visual and audible warnings when the RV reaches maximum safe leveling angles, typically around 6 degrees.

Reduced Risk of Equipment Damage

Your RV’s expensive appliances and systems stay protected through precise hydraulic leveling. Refrigerators, water heaters, and slide-outs require specific leveling tolerances to function properly and avoid premature failure.

Keep food fresh and organized with this 18.2 cu. ft. Kenmore refrigerator. It features adjustable glass shelves, humidity-controlled crispers, and fingerprint-resistant stainless steel.

Hydraulic systems maintain consistent pressure across all jacks, preventing the frame stress and potential damage that uneven manual leveling can cause. You’ll avoid costly repairs from appliance malfunctions caused by operating outside manufacturer specifications.

Pro #3: Time-Saving Convenience and Efficiency

When you’re eager to start your camping adventure, hydraulic leveling systems eliminate the tedious setup process that can eat into your precious outdoor time. This automated technology transforms what used to be a frustrating chore into a seamless part of your arrival routine.

Quick Setup and Deployment

You’ll complete your entire leveling process in under 2 minutes with hydraulic systems, compared to the 15-30 minutes required for manual methods. The system simultaneously operates all four jacks, measuring ground conditions and adjusting each corner independently. This parallel operation means you’re not crawling around checking bubble levels or making multiple adjustments. You can literally start unpacking your gear while the system finishes its final positioning adjustments.

This Firecore torpedo level ensures accurate measurements with its 3 vials (0°, 45°, 90°) and strong magnetic base for secure attachment to metal surfaces. Its durable, shockproof design and lightweight ABS housing make it ideal for various construction and home improvement projects.

One-Touch Operation Systems

Modern hydraulic leveling requires just a single button press to activate the entire sequence. You’ll monitor the progress from your comfortable driver’s seat or through smartphone apps on newer models. The system automatically detects when leveling is complete and locks the jacks in position. Some advanced systems even include memory settings that remember your preferred height adjustments for slide-outs or awnings, making repeat visits to favorite campsites even faster.

Pro #4: Improved Load Distribution and Support

Hydraulic leveling systems excel at distributing your RV’s weight evenly across all four corners. This balanced approach prevents stress concentration that damages frames and components over time.

Better Weight Management

Hydraulic systems automatically balance weight across all four jacks simultaneously, preventing dangerous corner loading that manual leveling often creates. Each jack receives precise pressure feedback, ensuring no single point bears excessive weight while others remain underloaded.

You’ll avoid the common manual leveling mistake of over-extending one jack while neglecting others. The system’s integrated sensors monitor weight distribution continuously, adjusting pressure as needed to maintain optimal balance across your RV’s entire footprint.

Enhanced Equipment Longevity

Proper load distribution significantly extends your RV’s structural lifespan by preventing frame twisting and component stress that leads to costly repairs. Refrigerators, slide-outs, and cabinets function optimally when weight distributes evenly.

Your interior systems benefit tremendously from consistent support. Doors align properly, drawers slide smoothly, and appliances operate without the stress-induced malfunctions common in poorly leveled RVs. This balanced foundation protects your investment for years longer than manual methods allow.

Con #1: Higher Initial Investment and Installation Costs

While hydraulic leveling systems deliver remarkable convenience and performance, they come with a substantial upfront price tag that can shock first-time buyers. You’ll need to budget significantly more than traditional manual leveling methods to get this advanced technology installed in your RV.

Equipment Purchase Expenses

Hydraulic leveling systems typically cost between $3,000 and $8,000 for the complete kit, depending on your RV’s size and weight capacity. Premium systems for large Class A motorhomes can exceed $10,000, while basic four-point systems for smaller travel trailers start around $2,500.

You’ll also need additional components like upgraded electrical systems, control panels, and safety switches. These extras can add another $500 to $1,500 to your total equipment costs, bringing the complete package well above what most RV owners initially budget for leveling solutions.

Professional Installation Requirements

Most hydraulic leveling systems require professional installation due to their complex hydraulic lines, electrical connections, and mounting requirements. Installation labor typically costs $1,500 to $3,000, depending on your RV’s configuration and local shop rates.

You can’t simply bolt these systems on like manual jacks – they require precise mounting, hydraulic line routing, and electrical integration with your RV’s systems. Many manufacturers void warranties if you attempt DIY installation, making professional setup essentially mandatory for protecting your investment.

Con #2: Increased Maintenance Requirements and Complexity

Hydraulic leveling systems demand significantly more attention than their manual counterparts. You’ll need to stay on top of regular maintenance schedules and develop familiarity with complex mechanical systems that can fail in multiple ways.

Regular System Inspections Needed

You’ll need to check hydraulic fluid levels monthly and inspect seals for leaks every few weeks. The system requires annual professional servicing to maintain warranty coverage, typically costing $200-400 per visit. Filter replacements, pressure testing, and component lubrication become routine expenses you can’t skip without risking system failure during your travels.

Specialized Repair Knowledge Required

When your hydraulic system breaks down, you can’t just grab basic tools and fix it yourself. These systems require specialized diagnostic equipment and hydraulic expertise that most RV technicians don’t possess. You’ll often need to locate certified repair facilities, which can be scarce in remote areas, leading to extended downtime and towing costs to reach qualified service centers.

Con #3: Potential for Hydraulic System Failures

Hydraulic leveling systems rely on pressurized fluid and mechanical components that can fail unexpectedly. When these failures occur, you’ll face both immediate inconvenience and potentially expensive repairs.

Fluid Leaks and Seal Problems

Hydraulic fluid leaks are the most common failure point in RV leveling systems. You’ll notice puddles of red or amber fluid under your jacks, indicating worn seals or damaged lines.

These leaks reduce system pressure, causing jacks to extend unevenly or fail completely. Replacement seals cost $50-150 per jack, but accessing them often requires removing flooring or exterior panels. Emergency repairs at remote campsites become nearly impossible without proper tools and replacement parts.

Environmental Impact Concerns

Hydraulic fluid leaking onto campground surfaces creates environmental hazards that can result in cleanup fees. Many state parks and private campgrounds charge $200-500 for soil remediation when hydraulic fluid contaminates their grounds.

The petroleum-based fluids used in most systems don’t biodegrade quickly and can harm local vegetation. Some eco-conscious campgrounds now restrict RVs with hydraulic systems due to leak risks. You’ll need to carry absorbent pads and cleanup materials to address spills immediately and avoid penalties.

Conclusion

Hydraulic leveling systems represent a significant advancement in RV technology that can transform your camping experience. While the initial investment and ongoing maintenance costs are substantial you’ll gain unmatched convenience precision and safety benefits.

Your decision should ultimately depend on your camping style and budget. If you frequently camp on uneven terrain or value quick setup times the investment makes sense. However if you’re comfortable with manual leveling and camp primarily at developed sites the added complexity might not justify the expense.

Consider your long-term RV plans and how often you’ll use the system. For full-time RVers or those who camp regularly hydraulic leveling often proves worthwhile despite the higher costs and maintenance requirements.

Frequently Asked Questions

What is hydraulic leveling technology in RVs?

Hydraulic leveling technology uses pressurized fluid and mechanical actuators to automatically adjust an RV’s stance on uneven terrain. The system includes hydraulic jacks at each corner, a pump, sensors, and a control panel. When activated, it measures tilt angles and adjusts jacks accordingly, capable of lifting up to 20,000 pounds per jack and completing the leveling process in under 2 minutes.

How much does a hydraulic leveling system cost?

Hydraulic leveling systems typically cost between $3,000 to $8,000, depending on your RV’s size and weight capacity. Premium systems for larger motorhomes can exceed $10,000. Professional installation adds another $1,500 to $3,000. The complexity requires professional setup to ensure proper integration and maintain warranty coverage.

What are the main advantages of hydraulic leveling systems?

The key advantages include superior precision (accurate to 0.5 degrees), significant time savings (under 2 minutes vs 15-30 minutes manually), enhanced safety features with automatic stabilization, and improved load distribution. The system eliminates manual effort, reduces physical risks, and protects expensive RV appliances from damage caused by improper leveling.

What maintenance do hydraulic leveling systems require?

Hydraulic systems need regular inspections of fluid levels and seals for leaks. Annual professional servicing is recommended to maintain warranty coverage, costing $200-$400 per visit. The systems require specialized repair knowledge, and most standard RV technicians may lack expertise to diagnose hydraulic issues, potentially leading to extended downtime.

What are the common problems with hydraulic leveling systems?

Common issues include fluid leaks and seal problems, which can cause uneven jack extension or complete system failure. These leaks create immediate inconvenience and costly repairs, as accessing replacement seals often requires significant disassembly. Environmental concerns also arise from hydraulic fluid spills, which may result in campground cleanup fees.

Which types of RVs typically have hydraulic leveling systems?

Hydraulic leveling systems are commonly found in Class A motorhomes, luxury fifth wheels, and larger travel trailers. This technology is particularly useful for boondocking and uneven campsites, as it can level RVs on slopes up to 6 degrees. The systems originated from construction equipment technology.