7 Insulation Solutions for Unconventional Dwellings That Maximize Every Inch

Discover 7 proven insulation solutions for tiny homes, shipping containers, and earthships. From spray foam to aerogel, find the perfect thermal barrier for your unique dwelling.

Why it matters: You’re living in a tiny house, converted shipping container, or earthship — but staying comfortable year-round requires smart insulation choices that traditional homes don’t face.

The challenge: Standard fiberglass batts and spray foam often won’t work for curved walls, metal structures, or spaces with extreme size constraints.

What’s ahead: Seven proven insulation solutions that’ll keep your unconventional dwelling cozy without breaking your budget or compromising your unique living space.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Spray Foam Insulation for Tiny Homes and Mobile Dwellings

Seal gaps and cracks up to 1 inch with Loctite Tite Foam. This durable, high-density polyurethane foam provides insulation and withstands building movement while adhering to various materials.

Spray foam delivers unmatched thermal performance in tight quarters where every inch counts. You’ll find it particularly valuable in tiny homes and RVs where traditional insulation methods leave gaps and thermal bridges.

Benefits of Closed-Cell Spray Foam

Closed-cell foam creates an airtight barrier that doubles as structural reinforcement for your walls. You’ll get R-6 to R-7 per inch compared to fiberglass’s R-3, meaning better insulation in half the space.

The moisture resistance prevents condensation issues that plague mobile dwellings. Your foam won’t sag or shift during travel like batts, maintaining consistent performance regardless of road vibrations or temperature swings.

Application Techniques for Small Spaces

Professional application works best in confined areas where overspray control matters most. You’ll need to mask everything thoroughly since foam bonds permanently to any surface it touches.

Work in thin passes rather than thick applications to prevent overheating and shrinkage. Focus on sealing all penetrations first – electrical boxes, plumbing runs, and wire chases – before filling larger cavities.

Cost Considerations and ROI

Expect to pay $1.50-$3.00 per square foot for professional closed-cell application in small dwellings. Your upfront investment typically pays back within 3-5 years through reduced heating and cooling costs.

Factor in the structural benefits when calculating ROI. The foam adds rigidity to thin walls and eliminates air leaks that force your HVAC system to work overtime in compact spaces.

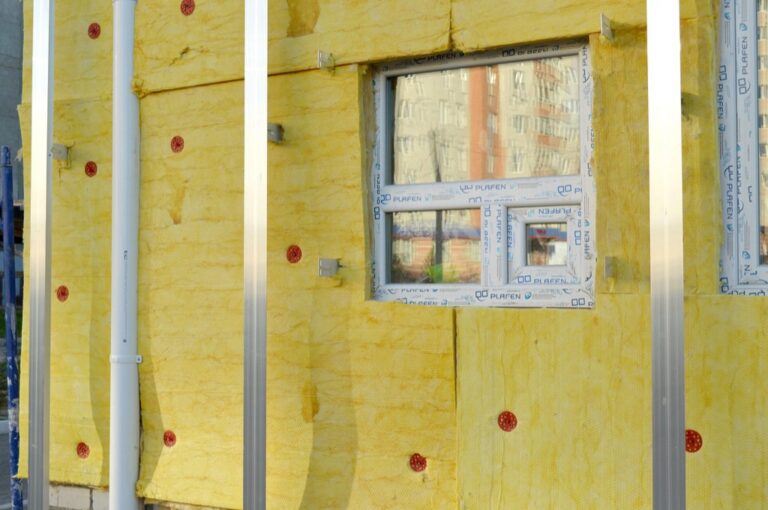

Reflective Insulation for Container Homes and Metal Structures

Reflect heat and insulate your space with this 48" x 10' double-reflective insulation. Made with premium aluminum foil and polyethylene bubbles, it's perfect for windows, RVs, and garage doors.

Metal structures create unique thermal challenges that traditional insulation can’t solve alone. Reflective insulation addresses radiant heat transfer, which accounts for up to 75% of heat gain in metal buildings.

Understanding Radiant Barrier Technology

Radiant barriers work by reflecting infrared radiation away from your living space rather than absorbing it. The aluminum foil surface reflects 97% of radiant heat, preventing it from penetrating your container walls.

Unlike traditional insulation that slows conductive heat transfer, reflective barriers create an air gap that interrupts radiant energy flow. This technology proves especially effective in hot climates where metal structures become solar ovens.

Installation Methods for Metal Surfaces

Mount reflective insulation directly to container ribs using adhesive strips or mechanical fasteners. Leave a minimum 3/4-inch air gap between the barrier and interior wall for maximum effectiveness.

Install the foil side facing the heat source – outward in hot climates, inward in cold regions. Seal all seams with reflective tape to maintain continuous coverage and prevent thermal bridging through fastener penetrations.

Moisture Control in Metal Dwellings

Condensation forms when warm, humid air contacts cold metal surfaces, creating potential mold and rust issues. Reflective insulation with vapor barriers prevents moisture from reaching the metal substrate.

Position the vapor barrier on the warm side of the assembly to block humid air infiltration. Ensure proper ventilation with exhaust fans and fresh air intake to manage humidity levels below 50% year-round.

Natural Fiber Insulation for Earthships and Eco-Homes

When you’re building with natural materials like adobe, rammed earth, or timber framing, synthetic insulation often feels like a contradiction. Natural fiber insulation aligns with eco-home principles while delivering the thermal performance these structures need.

Sheep’s Wool and Cotton Batt Options

Sheep’s wool insulation provides R-3.5 per inch and naturally regulates moisture without losing thermal performance. You’ll find it easiest to work with in timber-framed earthships where standard batt cavities exist.

Cotton batts made from recycled denim offer similar R-values with excellent fire resistance. They’re particularly effective in earth-bermed walls where you need consistent density and won’t compress over time like traditional batts might.

Hemp and Cellulose Alternatives

Hemp batts deliver R-3.7 per inch while naturally resisting mold and pests without chemical treatments. You can stuff them into irregular cavities common in cob construction, making them ideal for curved earthship walls.

Cellulose insulation works exceptionally well when blown into wall cavities between earthbags or tire walls. At R-3.8 per inch, it settles into every gap and provides excellent air sealing properties that complement earthship design principles.

Sustainability and Performance Comparison

| Material | R-Value per Inch | Moisture Handling | Fire Resistance | Cost per sq ft |

|---|---|---|---|---|

| Sheep’s Wool | R-3.5 | Excellent | Good | $1.20-$1.80 |

| Cotton Batts | R-3.4 | Good | Excellent | $0.90-$1.40 |

| Hemp | R-3.7 | Excellent | Good | $1.10-$1.60 |

| Cellulose | R-3.8 | Fair | Excellent | $0.75-$1.20 |

Reduce noise and improve sound quality with ATS Acoustics Cotton Batts. These recycled, Class-A fire-rated insulation batts resist microbial growth and won't cause skin irritation.

Natural fibers cost 20-40% more upfront than fiberglass but eliminate off-gassing concerns and support your eco-home’s environmental goals. They’ll maintain performance for 50+ years when properly installed.

Vacuum Insulated Panels for Space-Constrained Dwellings

When you’re working with walls that can’t spare even two inches for traditional insulation, vacuum insulated panels offer thermal performance that’ll change your entire approach. These space-age solutions deliver R-30 to R-60 performance in panels just half an inch thick.

Ultra-Thin High-Performance Solutions

VIP technology creates an evacuated core surrounded by reflective barriers, achieving thermal resistance impossible with conventional materials. You’ll get R-30 performance from a 0.4-inch panel compared to six inches of fiberglass for the same rating. This technology works by removing air molecules that transfer heat, leaving essentially nothing to conduct thermal energy through the panel core.

Best Applications for VIP Technology

Skoolies and van conversions benefit most from VIP installation since every inch of interior space matters for livability. Install panels behind kitchen cabinetry, bathroom walls, and sleeping areas where thickness restrictions make traditional insulation impractical. RV manufacturers increasingly use VIPs in slide-out sections and floor assemblies where structural limitations prevent thicker insulation layers.

Installation Challenges and Solutions

VIP installation requires extreme care since puncturing the vacuum seal destroys thermal performance permanently. Use adhesive mounting systems rather than mechanical fasteners, and protect panels with rigid backing during construction. Plan electrical and plumbing routes before installation since you can’t drill through completed panels without creating expensive thermal bridges.

Phase Change Material Insulation for Off-Grid Cabins

Keep your epinephrine autoinjector within the safe temperature range with the EPI-TEMP case. It uses PureTemp phase change material and features a durable design with allergy information pockets.

Phase change materials represent a breakthrough in thermal regulation for off-grid cabins, automatically storing and releasing heat as temperatures fluctuate. You’ll find PCM insulation particularly valuable in remote locations where consistent heating and cooling isn’t always available.

How PCM Technology Regulates Temperature

PCM insulation absorbs excess heat during warm periods and releases stored thermal energy when temperatures drop. The materials typically change from solid to liquid around 70-78°F, maintaining comfortable indoor temperatures without active heating or cooling systems.

You’ll experience fewer temperature swings throughout the day, as PCM panels can store up to 5 times more thermal energy per pound than traditional insulation materials like fiberglass.

Integration with Passive Solar Design

PCM insulation works exceptionally well with south-facing windows and thermal mass elements in your cabin design. The materials capture solar heat gained during sunny winter days and gradually release it during cold nights.

You can install PCM panels on interior walls that receive direct sunlight, creating a thermal battery effect. This combination reduces heating costs by 20-30% compared to conventional insulation alone in off-grid applications.

Maintenance and Longevity Factors

PCM insulation requires minimal maintenance once properly installed, with most systems lasting 20-30 years without performance degradation. The phase change process doesn’t wear out the materials, unlike mechanical heating and cooling systems.

You should inspect installation seams annually and ensure proper ventilation around PCM panels to prevent moisture buildup. Quality PCM products maintain their thermal properties through thousands of heating and cooling cycles.

Multi-Layer Insulation Systems for Converted Vehicles and RVs

Converting a vehicle into a livable space requires a sophisticated approach to insulation that goes beyond single-material solutions. Multi-layer systems address the unique challenges of mobile living while maximizing thermal efficiency in cramped quarters.

Combining Different Insulation Types

Layering different insulation materials creates superior thermal performance in vehicle conversions where space is at a premium. Start with a thin layer of closed-cell foam directly on metal surfaces to eliminate air gaps and provide moisture protection. Add reflective barriers facing air spaces to combat radiant heat transfer, then finish with natural fiber batts or rigid foam boards for bulk insulation. This combination typically achieves R-15 to R-20 in just 2-3 inches of wall thickness.

Addressing Thermal Bridging Issues

Metal framing and structural elements create thermal bridges that can reduce your insulation’s effectiveness by up to 40%. Combat this by installing continuous insulation boards over metal studs before adding interior paneling. Use thermal break materials like high-density foam strips between metal connections and living spaces. Focus special attention on wheel wells, door frames, and window installations where metal-to-metal contact creates the most significant heat loss pathways.

Weight Distribution Considerations

Every pound of insulation affects your vehicle’s handling and fuel economy, so strategic placement matters as much as material choice. Concentrate denser materials like closed-cell foam in lower wall sections and lighter options like reflective barriers in ceiling areas. Aim for total insulation weight under 200 pounds for standard van conversions. Document your weight distribution as you build—uneven loading can cause tire wear and handling issues that’ll cost more than the insulation savings.

Aerogel Insulation for Extreme Climate Dwellings

Insulate and save energy with roVa Shield Aerogel Coating. This easy-to-spray coating dries quickly to a smooth finish, providing excellent thermal insulation and reducing energy costs.

Aerogel stands as the ultimate insulation solution when your unconventional dwelling faces brutal temperature swings or space constraints that make conventional materials impractical. This NASA-developed material delivers unmatched thermal protection in situations where traditional insulation simply can’t perform.

Superior Thermal Performance Properties

Aerogel achieves R-10 per inch—nearly three times better than fiberglass and superior to any conventional material. The silica-based structure traps air in nanopores, creating thermal resistance that outperforms even vacuum panels in real-world conditions.

You’ll find aerogel maintains consistent performance from -100°F to 1200°F without degradation. Unlike spray foam that loses efficiency over time or natural fibers that compress, aerogel blankets retain their thermal properties indefinitely while remaining lightweight at just 0.1 pounds per cubic foot.

Applications in Harsh Weather Conditions

Arctic expeditions and desert research stations rely on aerogel when survival depends on thermal control. Your shipping container home in Alaska or tiny house in Death Valley benefits from the same technology that protects spacecraft.

Aerogel excels in applications where condensation poses risks—its hydrophobic properties prevent moisture absorption while maintaining breathability. You can install aerogel blankets directly against metal walls without vapor barriers, eliminating thermal bridging issues that plague other high-performance materials in extreme climates.

Cost-Benefit Analysis for Specialized Use

Aerogel costs $5-15 per square foot compared to $1-3 for conventional insulation, making it prohibitively expensive for whole-home applications. However, strategic use in critical areas—like roof sections or thermal bridges—delivers maximum impact for your investment.

Your payback timeline improves dramatically in extreme climates where heating costs exceed $200 monthly. Aerogel’s 50+ year lifespan and zero maintenance requirements offset initial costs, particularly when you factor in avoided structural modifications needed for thicker conventional materials.

Conclusion

Choosing the right insulation for your unconventional dwelling doesn’t have to be overwhelming. Each solution we’ve covered addresses specific challenges that traditional homes don’t face—from weight restrictions in RVs to thermal bridging in shipping containers.

Your success depends on matching the insulation type to your specific needs and budget. Whether you’re dealing with extreme temperatures that require aerogel’s superior performance or seeking sustainable options like natural fibers these solutions will keep you comfortable year-round.

The investment you make in proper insulation pays dividends through reduced energy costs improved comfort and better durability of your unique home. Start with your biggest thermal challenge first and build from there—your future self will thank you for the comfortable living space you’ve created.

Frequently Asked Questions

What makes spray foam insulation ideal for tiny houses and RVs?

Spray foam insulation provides exceptional thermal performance with R-6 to R-7 per inch compared to fiberglass’s R-3. It creates an airtight barrier, offers structural reinforcement, and resists moisture—perfect for mobile living. While the upfront cost ranges from $1.50-$3.00 per square foot, it typically pays back within 3-5 years through reduced energy costs.

How does reflective insulation work in metal structures like shipping containers?

Reflective insulation combats radiant heat transfer, which accounts for up to 75% of heat gain in metal buildings. Aluminum foil surfaces reflect 97% of radiant heat away from living spaces. For maximum effectiveness, install with an air gap and proper sealing to prevent thermal bridging and condensation issues.

What are the benefits of natural fiber insulation for eco-homes?

Natural fiber insulation options like sheep’s wool (R-3.5 per inch), cotton batts, hemp, and cellulose align with sustainable building practices. They eliminate off-gassing concerns, excel in moisture regulation, and can maintain performance for over 50 years. While more expensive upfront than fiberglass, they offer long-term value and environmental benefits.

Why are vacuum insulated panels (VIPs) perfect for space-constrained dwellings?

VIPs offer exceptional thermal performance with R-30 to R-60 ratings in panels just half an inch thick. This makes them ideal for van conversions and skoolies where space is premium. However, they require careful handling to avoid puncturing the vacuum seal and need professional installation planning.

How does phase change material (PCM) insulation regulate temperature automatically?

PCM insulation stores and releases heat as temperatures fluctuate, absorbing excess heat during warm periods and releasing it when temperatures drop. It can store up to five times more thermal energy per pound than fiberglass, reducing temperature swings and heating costs by 20-30% in off-grid applications.

What’s the best approach for insulating converted vehicles and RVs?

Multi-layer insulation systems work best, combining closed-cell foam for moisture protection, reflective barriers, and natural fiber batts or rigid foam boards. This approach can achieve R-15 to R-20 in just 2-3 inches while addressing thermal bridging issues and maintaining proper weight distribution under 200 pounds.

Is aerogel insulation worth the investment for extreme climate dwellings?

Aerogel insulation offers superior R-10 per inch performance and maintains consistency across wide temperature ranges. Its hydrophobic properties eliminate the need for vapor barriers, and its lightweight nature suits unconventional homes. While expensive initially, its long lifespan and low maintenance can justify the investment in harsh climates.