6 Best Marine Plywoods For Enclosed Trailer Floors That Nomads Swear By

A solid floor is vital for any rig. Discover the top 6 marine plywoods nomads rely on for superior durability and moisture protection in enclosed trailers.

You’ve just dragged home a new-to-you enclosed cargo trailer, the blank canvas for your dream adventure rig. Before you frame a single wall or plan your kitchen, you have to confront the foundation of your entire build: the floor. That factory-installed OSB or standard plywood floor is a ticking time bomb of moisture, delamination, and eventual rot. Choosing the right subfloor isn’t just a good idea; it’s the single most important decision you’ll make to ensure your home on wheels lasts.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Why Marine Plywood for Trailer Conversions?

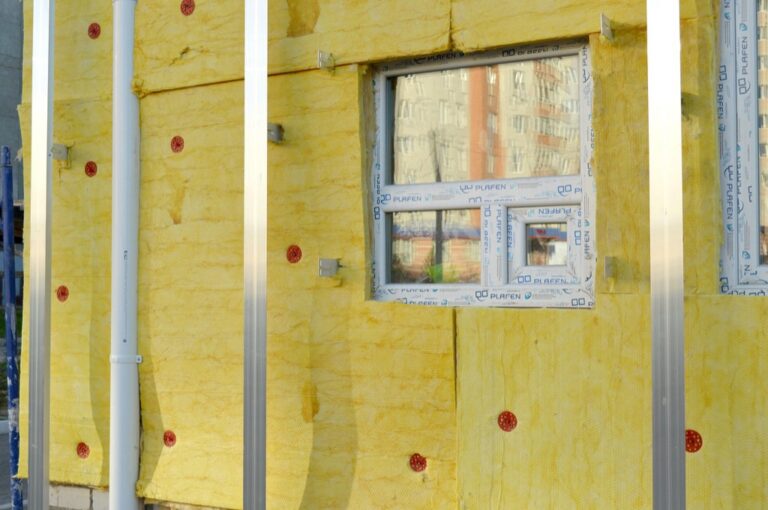

Let’s clear up a common misconception right away. Marine-grade plywood isn’t "waterproof wood." The wood itself is still wood. The magic lies in its construction: it’s laminated using 100% waterproof glue (like WBP – Water and Boil Proof) and, most importantly, its inner plies have zero voids. This is the critical difference between it and the exterior-grade plywood you find at a big-box store.

In a trailer conversion, this matters immensely. Your rig is a box that constantly flexes, vibrates, and endures massive temperature swings. Standard plywood has small air pockets, or voids, in its core layers. Moisture from road spray, a plumbing leak, or even condensation can find its way into these voids, get trapped, and begin rotting your floor from the inside out. The void-free core of marine plywood eliminates those weak spots, ensuring a solid, stable foundation that won’t delaminate under stress.

Yes, marine plywood is a significant investment upfront. But I’ve seen far too many nomads forced into a gut-wrenching, full-teardown repair after just a few years because their subfloor failed. Paying more now for a proper marine-grade foundation is your insurance policy against a catastrophic failure down the road. It’s the classic "build it once, build it right" philosophy, and on a trailer floor, it’s non-negotiable.

Joubert Okoume: The Lightweight Gold Standard

When every single pound counts against your trailer’s GVWR (Gross Vehicle Weight Rating), Joubert Okoume is the name you’ll hear whispered with reverence. Okoume is a tropical hardwood known for being exceptionally light and stable. Joubert, a French manufacturer, produces it to the highest BS 1088 marine-grade specification, resulting in a panel that is strong, consistent, and feathery light compared to the competition.

This weight savings is its superpower. Shaving 15-20 pounds per sheet might not sound like much, but across an entire 16-foot trailer floor, that can easily add up to 100 pounds or more. That’s extra capacity for water, batteries, or gear. For builders pushing the limits of their tow vehicle, this isn’t a luxury; it’s a necessity.

The trade-off for its low weight is its relative softness. Okoume dents more easily than denser hardwoods like Meranti or Fir. You have to be careful during the build process, as dropping a heavy tool can leave a mark. However, once your final flooring is installed over it, this becomes a non-issue. If your primary goal is building the lightest, most efficient rig possible, Joubert Okoume is the undisputed champion.

Hydrotek Meranti: Superior Durability & Strength

If your build plan involves heavy cabinetry, a massive battery bank, or hauling gear like motorcycles, you need a subfloor with serious brawn. This is where Hydrotek Meranti shines. Made from Meranti, a durable and dense species of mahogany, this plywood offers a significant step up in hardness, impact resistance, and screw-holding power compared to lightweight options.

Hydrotek is manufactured to the same rigorous BS 1088 standard, so you’re still getting the waterproof glue and void-free core. The key difference is the raw material. That added density means screws bite harder and hold tighter, which is crucial for securing cabinets and interior walls in a structure that’s constantly rattling down the highway. It provides a feeling of rock-solid security that’s hard to beat.

Of course, that strength comes at a cost: weight. A sheet of 3/4" Hydrotek Meranti is noticeably heavier than a sheet of Okoume. You have to weigh this against your trailer’s payload capacity. For a heavy-duty build where structural integrity is the top priority, the extra pounds are a worthwhile investment in long-term durability. It’s the go-to choice for nomads who are tough on their equipment.

Sapele Plywood: A Premium, Rot-Resistant Choice

For the builder seeking the ultimate peace of mind, Sapele marine plywood is a top-tier option. Sapele is an African hardwood, often compared to mahogany, that boasts impressive natural resistance to rot, decay, and insect attack. This inherent property provides a powerful second line of defense, complementing the waterproof glue and void-free construction.

This premium fir marine plywood is ideal for high-moisture environments. Its void-free construction and sanded surface ensure a smooth, seal-ready finish.

Sapele is a true triple-threat: it’s strong, stable, and naturally durable. This makes it an exceptional choice for builds in humid climates or for full-timers who will see all four seasons on the road. While you should always seal your plywood floor, starting with a wood that is naturally resistant to the elements gives you an unmatched level of protection.

This premium performance comes with a premium price tag and can sometimes be harder to source than more common marine plywoods. It’s a significant investment, no question. But for a "forever" rig or a no-compromise build, the long-term security and durability of a Sapele subfloor are worth every penny.

Bruynzeel Plywood: The Ultimate No-Void Option

Bruynzeel is the original. They literally invented marine plywood over 80 years ago, and their name is synonymous with uncompromising quality. Their claim to fame is a manufacturing process so precise that they can guarantee a truly void-free panel, a promise that is the holy grail for boat builders and high-end conversion specialists.

Why is a "guaranteed no-void" panel so important? Imagine drilling a screw to hold down a cabinet and hitting an air pocket instead of solid wood. The screw has no holding power. Worse, a small leak can introduce water into that void, creating a hidden pocket of rot that destroys your floor from within. Bruynzeel’s legendary quality control eliminates that risk entirely.

This level of perfection makes Bruynzeel one of the most expensive options available. For many DIY builders, it might be considered overkill. But if your budget allows, and you want the absolute certainty that your foundation is built on the best material money can buy, Bruynzeel is the answer. It’s the choice for those who believe in buying the best and only crying once.

Douglas Fir Marine: A Solid Domestic Workhorse

You don’t always have to look to imported hardwoods for a quality marine plywood. Douglas Fir, a staple of North American construction, makes for an excellent and often more affordable marine-grade panel. It’s incredibly strong and stiff for its weight, providing fantastic structural integrity for your trailer floor.

Unlike the BS 1088 imports, domestic marine plywood is typically graded by the APA – The Engineered Wood Association. Look for panels stamped as "Marine A-A" or "Marine A-B." While the standard allows for some very small, repaired knots or voids, it’s still a massive leap in quality over standard plywood and uses fully waterproof adhesive. It’s a workhorse material that gets the job done without the premium price of its exotic cousins.

The primary trade-offs are weight and rot resistance. Douglas Fir is heavier than Okoume and doesn’t have the natural decay resistance of Meranti or Sapele, making proper sealing absolutely critical. But for builders who value strength, availability, and a more reasonable price point, Douglas Fir marine plywood is a fantastic, pragmatic choice that will serve you well for years.

This premium fir marine plywood is ideal for high-moisture environments. Its void-free construction and sanded surface ensure a smooth, seal-ready panel.

Aqua-Tek Plywood: Reliable All-Weather Performer

Aqua-Tek is another highly respected name in the marine plywood world, often seen as a direct competitor to Hydrotek. Typically made from Meranti, it’s manufactured to the BS 1088 standard and has earned a reputation among builders for its consistency and reliability. When you’re buying multiple sheets for a floor, getting panels that are flat, uniform, and free of defects saves you a world of headaches during installation.

What sets brands like Aqua-Tek apart is their quality control. They deliver a consistently solid product that performs exactly as advertised. It provides the same benefits as other Meranti options: excellent strength, durability, and screw-holding power, making it a superb all-around choice for almost any trailer conversion.

In the real world, the choice between Aqua-Tek and a competitor like Hydrotek often comes down to what your local specialty lumberyard stocks and the price they offer. You can’t go wrong with either. Think of Aqua-Tek as another trusted, reliable tool in your arsenal for building a durable, long-lasting mobile home.

Sealing Your New Plywood Floor for Longevity

Buying the best marine plywood on the market is only half the battle. I cannot stress this enough: marine plywood is water-resistant, not waterproof. The glue won’t fail when wet, but the wood veneers themselves will absolutely absorb water and rot if left unprotected. Sealing it is not an optional step.

The only correct way to seal your subfloor is to coat all six sides of every single piece before you install it. That means the top, the bottom, and every factory and freshly cut edge. The end grain on the edges is like a bundle of tiny straws, and it will wick up moisture faster than any other surface. Skipping the edges is a recipe for disaster.

For the best possible protection, use a two-part penetrating epoxy sealer. This soaks deep into the wood fibers before hardening, creating an impermeable plastic-like barrier. High-quality, oil-based exterior primer or marine-grade varnish are also good options. Whatever you choose, apply at least two generous coats and let it cure completely. This meticulous prep work is what separates a build that lasts five years from one that lasts twenty.

This 2-part penetrating epoxy resin seals and hardens wood, effectively stopping rot and preparing surfaces for finishes. Its low viscosity penetrates all wood types, making it ideal for restoration and repair projects.

Your trailer’s floor is more than just a surface to walk on; it’s the structural and environmental barrier protecting your entire home from the road. Choosing a quality marine plywood—whether you prioritize the light weight of Okoume or the brute strength of Meranti—and sealing it meticulously is a foundational act of self-reliance. It’s a tough, expensive job upfront, but the peace of mind you’ll have rolling down a rain-soaked highway is absolutely priceless.