6 Best RV Wire Nuts For Vibration Resistance That Nomads Swear By

Road vibrations can loosen standard wire nuts, risking electrical failure. Discover the 6 best options nomads trust for secure, vibration-proof connections.

You hear it after a long, bumpy drive down a washboard road—a faint buzz from a light fixture, or worse, an outlet that’s suddenly dead. In a stationary house, a loose wire is rare, but in a home that’s also a vehicle, it’s an inevitability. This is why choosing the right wire connector is one of the most critical, yet overlooked, aspects of a safe and reliable RV electrical system.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Why Standard Wire Nuts Fail in a Bouncing RV

The traditional twist-on wire nuts you find at any hardware store are brilliant for residential wiring. They use a conical spring to bite into and twist copper wires together, creating a solid connection inside the walls of a house that never moves. But an RV is not a house. It’s a controlled earthquake on wheels.

Every mile you travel, every pothole you hit, sends micro-vibrations through your rig’s entire structure, including the electrical wiring. Over time, these vibrations can work a standard wire nut loose. The spring’s tension eases, the connection becomes intermittent, and you get flickering lights. More dangerously, a loose connection creates resistance, which generates heat and can lead to arcing—a primary cause of electrical fires.

It’s not a question of if a standard wire nut will fail, but when. They simply weren’t designed for a dynamic environment. Using them in an RV is like using wood screws to hold an engine together; you’re using the wrong tool for a high-vibration job, and the consequences can be serious.

WAGO 221 Lever-Nuts: The RVer’s Go-To Choice

Quickly and reliably connect solid, stranded, and flexible copper wires with this 28-piece WAGO 221 Lever Nut assortment. The transparent housing allows for visual inspection of proper wire insertion, and the kit includes a variety of sizes (2-5 conductor) for diverse wiring needs.

If there’s one connector that has revolutionized RV wiring, it’s the WAGO 221 Lever-Nut. Instead of a twisting spring, these connectors use a small lever to open a spring-loaded clamp. You simply lift the lever, insert your stripped wire, and snap the lever shut.

The genius is in the constant pressure. The internal spring clamp maintains a firm, consistent grip on the wire that doesn’t loosen with vibration. The clear housing is another huge benefit, as you can visually confirm that the wire is seated properly, eliminating any guesswork. They also excel at joining different wire types and sizes, like the solid wire from a light fixture to the stranded wire common in RVs.

Are they perfect? Not quite. They are bulkier than a traditional wire nut, which can be a challenge in a crowded junction box. They also cost significantly more per connection. But for interior wiring that needs to be absolutely dependable and easy to service, most seasoned RV builders agree the peace of mind is well worth the extra cost and space.

TICONN Heat Shrink Butt Connectors for a Sealed Joint

When you move to exterior wiring or any area exposed to moisture, you need more than just a vibration-resistant connection—you need a sealed one. This is where heat shrink butt connectors shine. These are crimp-style connectors sheathed in a special tubing that contains a heat-activated adhesive.

The process is straightforward but requires the right tools. You crimp each end of the connector onto your wires using a proper crimping tool, creating a strong mechanical bond. Then, you gently heat the connector with a heat gun. The tubing shrinks tightly around the wire, and an internal ring of adhesive melts, creating a completely waterproof and corrosion-proof seal.

This method is ideal for wiring underbelly lights, backup cameras, water pumps, or anything exposed to road spray and the elements. The main tradeoff is that it’s a permanent connection. You can’t easily undo it, and you need to invest in a quality ratcheting crimper for a reliable result. A bad crimp will fail, seal or no seal.

Crimp insulated terminals onto 10-22 AWG wire with ease using this ratcheting tool. Its adjustable design delivers powerful, consistent crimps across three terminal sizes.

Posi-Lock Connectors: A Secure & Reusable Solution

Posi-Lock connectors are a bit of an outlier, but they have a fiercely loyal following for good reason. They require no tools and create an incredibly strong mechanical connection that’s practically immune to vibration. The patented design works by sandwiching the wire between a central metal cone and a threaded body, creating a connection you can trust.

Their biggest advantage is reusability. You can unscrew a Posi-Lock, make a change, and screw it back together dozens of times without degrading the connection or the wire. This makes them perfect for troubleshooting, temporary hookups, or connecting components you might want to upgrade later, like a stereo system or solar charge controller.

The downside is that they are the bulkiest option on this list and are not inherently waterproof. While they create a fantastic electrical and mechanical connection, you’d need to add your own heat shrink tubing over them for any exterior applications. They’re a specialized solution for when serviceability is your top priority.

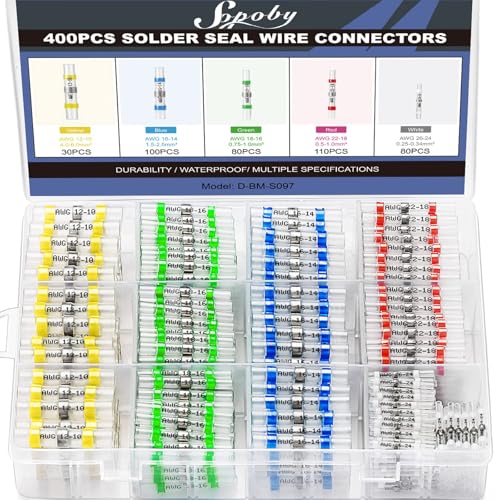

Sopoby Solder Seal Connectors for Ultimate Strength

For the most critical connections where failure is simply not an option, solder seal connectors offer the ultimate bond. These clever devices combine four functions into one piece: they solder, insulate, seal, and provide strain relief all at once. Each connector is a transparent heat-shrink tube containing a pre-measured ring of low-temperature solder and two rings of adhesive sealant.

You simply slide the connector over your twisted wires, position the solder ring over the copper, and apply heat. The solder melts and flows into the wire strands, creating a permanent, soldered joint, while the tubing shrinks and the adhesive rings melt to form a waterproof seal. The result is a connection that is as strong as the wire itself.

This is the go-to for engine bay wiring, permanent solar connections, or any circuit that is absolutely essential. The main caution is that it requires some practice. You need a good heat gun and a careful hand to melt the solder properly without scorching the insulation. It’s a one-shot deal—once it’s done, it’s done for good.

Ideal In-Sure Push-In Connectors: Fast and Firm

Think of push-in connectors as the faster, simpler sibling of the WAGO Lever-Nut. Instead of a lever, they use an internal spring-loaded tine that allows a wire to be pushed in but not pulled out. For a quick and secure connection, nothing is faster. You just strip your wire to the correct length and push it firmly into the port.

These are fantastic for jobs where you’re making many similar connections, like installing a series of new puck lights. Their compact size is also a major advantage in tight spaces. They provide a very firm grip that holds up well to the rigors of the road.

However, there’s a critical caveat: most push-in connectors are designed primarily for solid-core wire. While some newer models are rated for stranded wire, it can be a real challenge to insert the fine strands without them bunching up. They are also generally considered a one-time-use product; removing a wire can damage the internal gripping mechanism, making a secure reconnection impossible.

DryConn Silicone-Filled Nuts for Wet Locations

Sometimes, the best solution combines old and new technology. DryConn (and similar brands) take the familiar shape of a twist-on wire nut but pre-fill it with a thick, non-hardening silicone sealant. They are specifically designed for direct burial or extremely wet locations.

As you twist the nut onto the wires, the silicone is forced into and around the connection, completely encapsulating it. This creates a formidable barrier against water, moisture, and corrosion, making them an excellent choice for exterior junction boxes or wiring for your water pump and tanks.

The connection itself is still a traditional spring, so it carries some of the same vibration concerns as a standard nut. However, the thick silicone provides significant dampening and support, making it far more robust than a dry nut. Just be prepared for a bit of a mess—that silicone gets everywhere, and they are strictly a one-time-use connector.

Matching the Connector to Your RV Electrical Job

There is no single "best" wire connector for an RV. The right choice always depends on the specific job. Trying to use one type for everything will lead to frustration and potential failure. Instead, think like a pro and build a small toolkit of different connectors for different tasks.

Here’s a simple framework for making the right choice:

- General Interior Wiring (Lights, Outlets, Switches): WAGO 221 Lever-Nuts are the champion here. They are secure, easy to use, and reusable.

- Exterior & Wet Locations (Pumps, Undercarriage Lights): TICONN Heat Shrink Butt Connectors or DryConn Silicone-Filled Nuts are your best bet for a fully sealed, corrosion-proof joint.

- Critical, Permanent Connections (Solar, Inverter): Sopoby Solder Seal Connectors provide the strongest and most reliable bond possible.

- Frequently Serviced Connections (Stereo, Dash Cams): Posi-Lock Connectors offer unmatched strength and reusability without any special tools.

By understanding the strengths and weaknesses of each type, you can move beyond simply connecting wires and start building an electrical system that’s as resilient and reliable as the rest of your rig.

Ultimately, the small details determine whether your RV feels like a reliable home or a constant project. Choosing a vibration-proof wire connector isn’t just about preventing a flickering light; it’s about investing in the safety, security, and peace of mind you need to truly enjoy life on the road.