6 Best UV Resistant Sealants For Boat Trailer Repairs That Boaters Swear By

Protect your boat trailer from sun damage. Our guide reviews 6 top-rated, UV-resistant sealants for durable, flexible, and waterproof repairs that last.

You’ve just noticed it: a small gap opening up on your boat trailer’s fender, or the seal around a taillight looking cracked and chalky. It’s tempting to grab any old tube of caulk from the garage, but that’s a fast track to doing the same job again next season. Your boat trailer lives a harsh life, constantly baked by the sun and splashed with water, so the sealant you choose is a critical line of defense against rust and rot.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Why UV-Resistance is Crucial for Trailers

Think of your trailer sitting in the driveway or a storage lot. It’s exposed to direct sunlight for hours, days, and weeks on end. That constant bombardment of ultraviolet radiation is brutal on plastics and polymers, which is exactly what most sealants are made of.

Without proper UV resistance, a sealant will degrade surprisingly quickly. It starts by losing its flexibility, becoming brittle and hard. Then, you’ll see fine cracks appear, which eventually grow, breaking the waterproof seal you worked so hard to create. The sealant might also turn yellow and chalky, flaking away and leaving the underlying joint exposed. This isn’t just an aesthetic problem; it’s an open invitation for water to seep into your trailer’s frame, wiring, and hardware, leading to corrosion and electrical failures down the road.

3M 5200 Marine Sealant: The Permanent Bond

Bond and seal your boat or RV with 3M Marine Adhesive Sealant 5200 for a durable, waterproof repair. This fast-curing, one-part polyurethane polymer creates a permanent bond that resists weathering and vibration, above or below the waterline.

When you need to bond something to your trailer and you never, ever want it to come off again, you reach for 3M 5200. This stuff is legendary in the boating world for a reason. It’s a polyurethane adhesive sealant that creates an astonishingly strong, permanent, and completely waterproof bond that is highly resistant to UV rays, weathering, and saltwater.

Use 5200 for structural components you don’t plan on servicing. Think mounting bunk brackets, permanently attaching fenders, or sealing through-frame bolts. The tradeoff for this incredible strength is its permanence. If you use 5200 to bed a taillight, you’ll likely have to destroy the light fixture to remove it later. Its cure time is also very long—it can take up to a week to fully cure—so this isn’t the product for a quick, last-minute fix before hitting the road.

Sikaflex-291: Flexible and Paintable Seal

Sikaflex-291 is a fast-curing, all-purpose marine adhesive and sealant with excellent adhesion to various boat materials. It offers superior durability and performance both above and below the waterline, and is NSF/USDA approved.

Sikaflex-291 is the perfect counterpoint to 3M 5200. It’s also a marine-grade polyurethane sealant, but it’s designed to be a tough, flexible sealant rather than a permanent adhesive. This makes it far more versatile for general trailer repairs. It maintains excellent elasticity after curing, allowing it to absorb the vibrations and shocks of the road without cracking or losing its seal.

The real advantage of Sikaflex-291 is its balance of features. It offers fantastic UV resistance and adhesion to a wide variety of materials, from metal to wood to fiberglass. Crucially, it remains removable if you need to service a part down the line. It’s also paintable, which is a huge plus for visible repairs on painted trailer frames. Use it for bedding deck hardware, sealing around windows or lights, and filling joints where some movement is expected.

Loctite PL Marine: Fast Curing for Quick Fixes

Sometimes you don’t have a week to wait for a sealant to cure. That’s where Loctite PL Marine Fast Cure Adhesive Sealant comes in. This is your go-to for strong, waterproof repairs that need to be ready fast. It becomes tack-free in under an hour and can be exposed to water in just 24 hours, making it ideal for those weekend repair jobs.

This fast-cure adhesive sealant creates a watertight, flexible bond for marine applications like hull joints and deck fittings. It's ideal for fiberglass, vinyl, and glass, offering reliable performance above or below the waterline once cured.

Despite its speed, it doesn’t skimp on performance. It’s a hybrid sealant that bonds aggressively to most surfaces and offers excellent UV resistance, so it won’t yellow or crack in the sun. It’s great for sealing gaps around hardware, re-attaching trim pieces, or fixing a leaky seam when you’re short on time. It provides a strong but flexible bond that can handle the bumps and jostles of trailering.

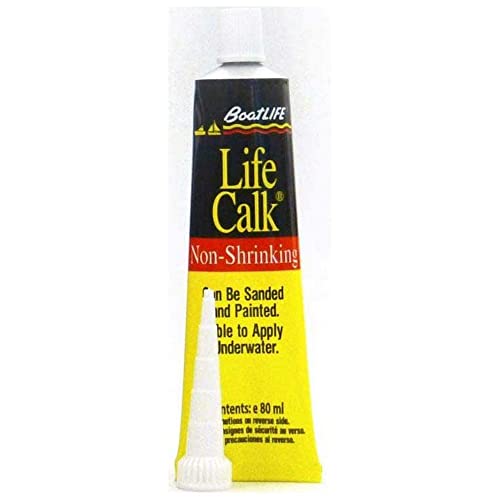

BoatLIFE Life-Calk Polysulfide Sealant

BoatLIFE Life-Calk Sealant provides a durable, non-shrinking seal for your boat. This 2.8 fl. oz. black sealant offers reliable protection against the elements.

Before the modern polyurethanes took over, polysulfide sealants like BoatLIFE Life-Calk were the standard for marine applications, and they still have a dedicated following. This sealant is a workhorse. It offers a tenacious, permanently flexible bond that is especially resistant to chemicals, including teak oils, gasoline, and diesel fuel. This makes it a great choice for sealing areas near your fuel tank or other spots that might see chemical exposure.

Life-Calk is known for its incredible longevity and UV stability. It’s a two-part sealant, meaning you have to mix it before application, which can be a bit more work. However, this chemistry results in a cure that is exceptionally tough and durable. It’s an excellent choice for sealing joints in wooden components or bedding hardware where you need a bombproof, long-lasting seal that can withstand a harsh environment.

Lexel Clear Sealant: Tougher Than Silicone

Seal leaks and bond materials with Lexel Adhesive Caulk. This clear, paintable sealant sticks to wet surfaces for a durable, waterproof bond.

When you need a seal that’s crystal clear and tough as nails, Lexel is in a class of its own. It’s marketed as being "19 times clearer than silicone" and won’t yellow over time, making it perfect for sealing around trailer lights or windows where you don’t want a cloudy or visible caulk line. It looks like water in the tube and it dries perfectly transparent.

But Lexel isn’t just about looks. It’s a co-polymer rubber-based sealant that is incredibly elastic, able to stretch and compress with joint movement without tearing. It sticks to almost anything—even damp surfaces—and is fully paintable. Think of it as a superior alternative to silicone for sealing dissimilar materials or for any application where absolute clarity and extreme flexibility are paramount.

GE Marine Silicone: A Trusted Waterproof Barrier

While some advanced sealants have surpassed it in specific areas, a high-quality 100% silicone sealant still has its place. GE Marine Silicone is a reliable, widely available, and affordable option for creating a waterproof, flexible seal. Its primary strength is its incredible resistance to UV degradation and its ability to remain flexible even after years of sun exposure.

Silicone is best used for sealing tasks where adhesion strength isn’t the top priority. It’s perfect for creating a waterproof gasket around light fixtures, sealing small gaps in non-structural areas, or waterproofing electrical connections. The main drawback is that nothing sticks to cured silicone, not even paint or more silicone. This means surface prep is critical, and you can’t paint over it to match your trailer’s color.

Applying Sealant for a Long-Lasting Repair

The best sealant in the world will fail if you don’t apply it correctly. The single most important step is surface preparation. The surfaces must be completely clean, dry, and free of any old sealant, dirt, grease, or flaky paint. Use a solvent like acetone or denatured alcohol to wipe the area down right before you apply the new bead.

For a professional-looking job, use painter’s tape to mask off both sides of the joint, leaving a clean gap for the sealant. After applying the bead, "tool" it by running a moistened finger or a specialized tool along the bead to press the sealant into the joint and smooth the surface. This ensures good contact and a clean, concave finish.

Finally, pay attention to the cure time listed on the tube. Don’t rush it. Respecting the manufacturer’s instructions for temperature, humidity, and cure time is the difference between a repair that lasts a decade and one that fails in a year.

Choosing the right sealant isn’t about finding one magic tube that does everything; it’s about matching the product’s strengths to the specific demands of the repair. Whether you need the permanent grip of 5200 or the fast-curing convenience of Loctite, using the right tool for the job ensures your trailer stays solid, dry, and ready for the next launch. Don’t skimp here—a few extra dollars on the right sealant buys you years of peace of mind.